Ts'ebetso ea tlhahiso ea mabili a koloi ea aluminium alloy e arotsoe haholo ka mekhahlelo e latelang:

1. Mokhoa oa ho lahla:

• Gravity casting: Tšela motsoako oa aluminiamo oa metsi ka har'a hlobo, tlatsa hlobo tlas'a matla a khoheli 'me ue pholise hore e be sebōpeho. Ts'ebetso ena e na le matsete a thepa e tlase le ts'ebetso e batlang e le bonolo, e loketseng tlhahiso e nyane. Leha ho le joalo, ts'ebetso ea ho lahla e tlase, boleng ba boleng ba sehlahisoa bo fokola, 'me liphoso tse kang li-pores le shrinkage li atisa ho etsahala.

• Khatello e tlase ea khatello: Ka crucible e tiisitsoeng, mokelikeli oa aluminium alloy o hatelloa ka har'a hlobo ka khatello e tlaase ka khase e sa sebetseng ho e tiisa tlas'a khatello. Li-castings tse hlahisoang ke ts'ebetso ena li na le sebopeho se teteaneng, boleng bo botle ba ka hare, ts'ebetso e phahameng ea tlhahiso, 'me e loketse tlhahiso ea bongata, empa thepa ea thepa e ngata, litlhoko tsa hlobo li phahame, le litšenyehelo tsa hlobo li phahame haholo.

• Spin casting: Ke ts'ebetso e ntlafalitsoeng e ipapisitseng le khatello e tlase ea khatello. Ntlha ea pele, sekheo sa lebili se thehoa ka ho theola khatello e tlaase, ebe sekheo se behoa mochine o ohlang. Sebopeho sa karolo ea rim se holofala butle-butle mme se atolosoa ke hlobo e potolohang le khatello. Ts'ebetso ena ha e boloke feela melemo ea ho lahlela khatello e tlase, empa hape e ntlafatsa matla le ho nepahala ha lebili, ha e ntse e fokotsa boima ba lebili.

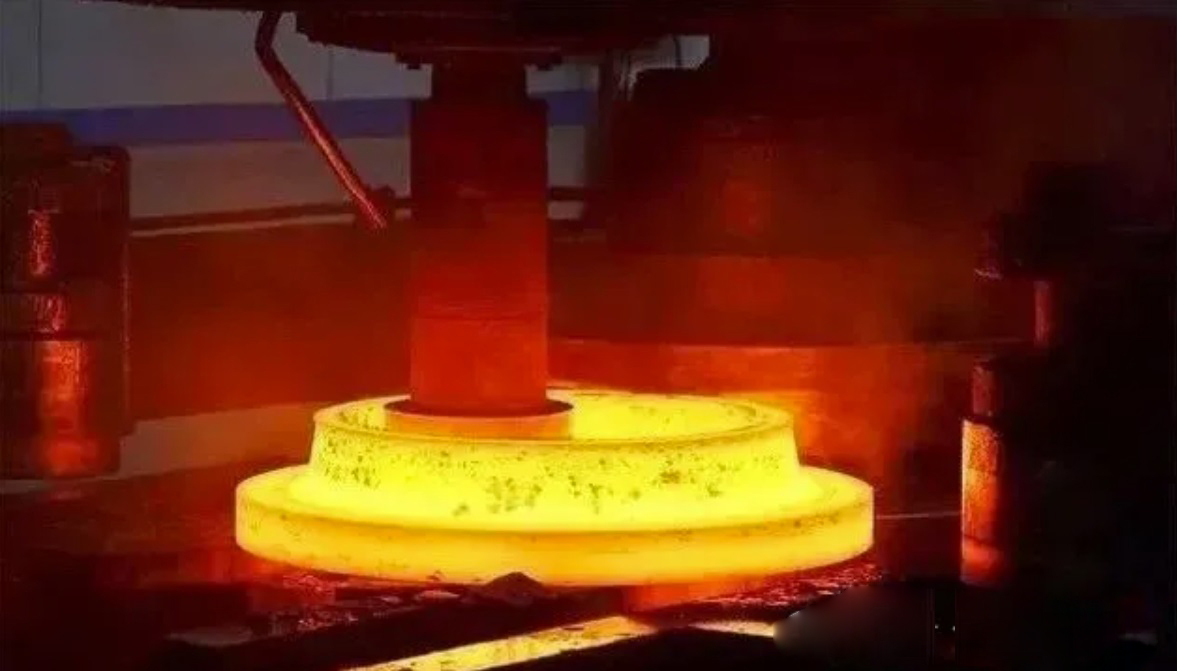

2. Mokhoa oa ho theha

Ka mor'a hore motsoako oa aluminium o futhumale mocheso o itseng, o etsoa hlobo ka mochine oa khatiso oa forging. Mekhoa ea ho lokisa e ka aroloa ka mefuta e 'meli e latelang:

• Ho qhekella ho tloaelehileng: Karolo e feletseng ea ingot ea aluminium e etsoa ka ho toba ka sebōpeho sa lebili tlas'a khatello e phahameng. Lebili le hlahisoang ke ts'ebetso ena le na le ts'ebeliso e phahameng ea thepa, litšila tse fokolang, lisebelisoa tse ntle tsa mochini oa forgings, le matla a matle le ho tiea. Leha ho le joalo, matsete a lisebelisoa a maholo, ts'ebetso e rarahane, 'me boemo ba botekgeniki ba opareitara bo hlokahala hore bo be bo phahameng.

• Semi-solid forging: Ea pele, motsoako oa aluminium o futhumatsoa ho fihlela boemong bo tiileng, ka nako eo motsoako oa aluminium o nang le mokelikeli o itseng le ho khoneha, ebe o etsoa. Ts'ebetso ena e ka fokotsa tšebeliso ea matla ts'ebetsong ea forging, ea ntlafatsa ts'ebetso ea tlhahiso, hape ea ntlafatsa boleng ba lebili.

3. Ts'ebetso ea welding

Letlapa le phuthoa ka har'a silinda le ho chesetsoa, 'me le sebetsoa feela kapa le hatelloa ka har'a rim ea lebili le nang le hlobo, ebe disc ea lebili la pre-cast e chesetsoa ho hlahisa lebili. Mokhoa oa ho tjheseletsa e ka ba laser welding, electron beam welding, joalo-joalo Ts'ebetso ena e hloka mohala o inehetseng oa tlhahiso o nang le katleho e phahameng ea tlhahiso 'me o loketse tlhahiso ea boima, empa ponahalo e futsanehile le mathata a boleng ba ho tjheseletsa a atisa ho etsahala libakeng tsa welding.

Nako ea poso: Nov-27-2024