1.Selelekela

Ho lokisa boima ba likoloi ho qalile linaheng tse tsoetseng pele 'me qalong ho ne ho etelletsoe pele ke linatla tsa likoloi tsa setso. Ka tsoelo-pele e tsoelang pele, e fumane matla a bohlokoa. Ho tloha nakong eo Maindia a neng a sebelisa motsoako oa aluminium ka lekhetlo la pele ho hlahisa li-crankshafts tsa likoloi ho fihlela tlhahiso ea pele ea boima ba Audi ea likoloi tsa aluminium kaofela ka 1999, motsoako oa aluminium o bone khōlo e matla ea lisebelisoa tsa likoloi ka lebaka la melemo ea eona e kang boima bo tlaase, matla a itseng a phahameng le ho satalla, boleng bo botle le ho satalla, sekhahla se phahameng sa ho tsosolosoa, ho hanyetsa le ho tsosolosoa ho matla. Ka 2015, karolo ea kopo ea motsoako oa aluminium likoloing e ne e se e fetile 35%.

Mabone a likoloi a China a qalile ka tlase ho lilemo tse 10 tse fetileng, 'me boemo ba theknoloji le ts'ebeliso bo salletse morao ho linaha tse tsoetseng pele joalo ka Jeremane, United States le Japane. Leha ho le joalo, ka nts'etsopele ea likoloi tse ncha tsa matla, khanya ea thepa e ntse e tsoela pele ka potlako. Ka lebaka la ho phahama ha likoloi tse ncha tse nang le matla, theknoloji ea China ea mabone a bobebe e bonts'a mokhoa oa ho ts'oara linaha tse tsoetseng pele.

Mmaraka oa China oa thepa e bobebe o moholo. Ka lehlakoreng le leng, ha ho bapisoa le linaha tse tsoetseng pele linaheng tse ling, theknoloji ea China ea ho khantša e qalile morao, 'me boima ba koloi ea Curb bo boholoanyane. Ha ho nahanoa ka tekanyo ea karolo ea thepa e bobebe linaheng tse ling, ho ntse ho na le sebaka se lekaneng sa nts'etsopele China. Ka lehlakoreng le leng, e susumetsoang ke maano, nts'etsopele e potlakileng ea indasteri e ncha ea likoloi tsa matla a China e tla phahamisa tlhokahalo ea lisebelisoa tse bobebe le ho khothaletsa lik'hamphani tsa makoloi hore li hatele pele ho fokotsa boima ba 'mele.

Ntlafatso ea maemo a tlhahiso le tšebeliso ea mafura e qobella ho potlakisa mabone a koloi. China e ile ea kenya ts'ebetsong ka botlalo litekanyetso tsa tlhahiso ea China VI ho 2020. Ho ea ka "Mokhoa oa Tlhahlobo le Lipontšo tsa Tšebeliso ea Mafura a Likoloi tsa Bapalami" le "Mokhoa oa ho Boloka Matla le New Energy Vehicle Technology Roadmap," tekanyetso ea tšebeliso ea mafura ea 5.0 L / km. Ha ho nahanoa ka sebaka se lekanyelitsoeng sa tsoelo-pele e kholo ho thekenoloji ea enjene le phokotso ea mesi, ho nka mehato ea likarolo tsa koloi tse bobebe ho ka fokotsa ka nepo tlhahiso ea likoloi le tšebeliso ea mafura. Ho fokotsa boima ba likoloi tse ncha tsa motlakase ho fetohile tsela ea bohlokoa bakeng sa nts'etsopele ea indasteri.

Ka selemo sa 2016, Mokhatlo oa Chaena oa Boenjiniere ba Likoloi o ile oa fana ka "Molao oa Tsela ea ho Boloka Matla le New Energy Vehicle Technology Roadmap," e neng e rerile lintlha tse kang tšebeliso ea matla, sebaka sa ho tsamaea ka sekepe, le lisebelisoa tsa tlhahiso ea likoloi tse ncha tsa matla ho tloha 2020 ho ea 2030. Lightweighting e tla ba tataiso ea bohlokoa bakeng sa tsoelo-pele ea nakong e tlang ea likoloi tse ncha tsa matla. Ho bobebe ho ka eketsa sebaka sa ho tsamaea le ho rarolla "matšoenyeho a mangata" likoloing tse ncha tsa matla. Ka tlhokahalo e ntseng e eketseha ea sebaka se atolositsoeng sa ho tsamaea ka sekepe, ho potlaka ha likoloi ho ntse ho potlaka, 'me thekiso ea makoloi a macha e eketsehile haholo lilemong tsa morao tjena. Ho latela litlhoko tsa sistimi ea lintlha le "Leano la Ntlafatso ea Nako e Bohareng ho isa ho Nako e telele bakeng sa Indasteri ea Likoloi," ho hakanngoa hore ka 2025, thekiso ea likoloi tse ncha tsa China e tla feta li-unit tse limilione tse 6, ka sekhahla sa kholo ea selemo le selemo se fetang 38%.

2.Aluminium Alloy Litšobotsi le Likopo

2.1 Litšobotsi tsa Aluminium Alloy

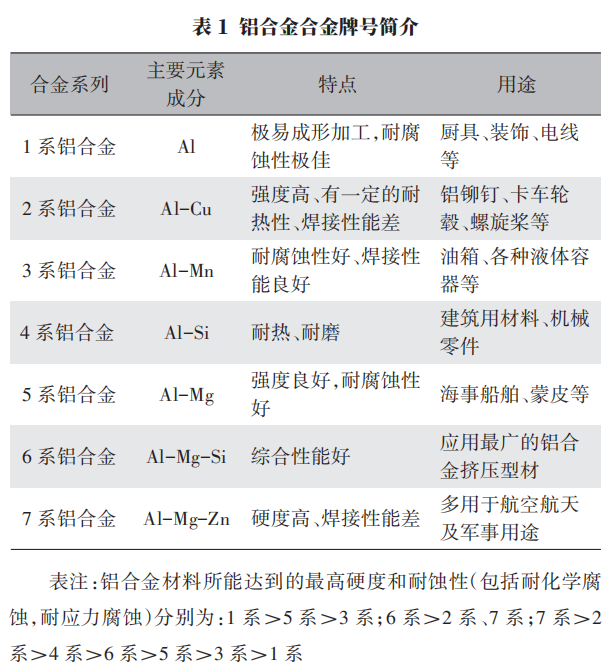

Boima ba aluminium ke karolo ea boraro ea tšepe, e etsang hore e be bobebe. E na le matla a khethehileng a phahameng, bokhoni bo botle ba extrusion, khanyetso e matla ea kutu, le ho sebelisoa hape ho phahameng. Li-alloys tsa aluminium li khetholloa ka hore li entsoe ka magnesium haholo-holo, li bonts'a ho hanyetsa mocheso o motle, thepa e ntle ea ho cheselletsa, matla a mokhathala o motle, ho se khone ho matlafatsoa ke phekolo ea mocheso, le bokhoni ba ho eketsa matla ka ho sebetsa ha serame. Letoto la 6 le khetholloa ka ho qaptjoa ka ho khetheha ka magnesium le silicon, le Mg2Si e le karolo e ka sehloohong ea ho matlafatsa. Li-alloys tse sebelisoang haholo sehlopheng sena ke 6063, 6061, le 6005A. 5052 aluminium plate ke AL-Mg series alloy aluminium plate, e nang le magnesium e le eona ntho e ka sehloohong ea motsoako. Ke motsoako o sebelisoang ka ho fetisisa oa anti-rust aluminium alloy. Alloy ena e na le matla a phahameng, matla a phahameng a mokhathala, polasetiki e ntle le ho hanyetsa kutu, e ke ke ea matlafatsoa ke phekolo ea mocheso, e na le polasetiki e ntle mosebetsing o thata o batang, o tlaase oa polasetiki mosebetsing o batang o thata, o hanyetsanang le kutu, le thepa e ntle ea welding. E sebelisoa haholo-holo bakeng sa likarolo tse kang liphanele tse ka mahlakoreng, likoahelo tsa marulelo, le liphanele tsa mamati. 6063 aluminium alloy ke motsoako o matlafatsang o phekolehang mocheso letotong la AL-Mg-Si, ka magnesium le silicon e le likarolo tsa mantlha tsa motsoako. Ke profil ea aluminium e matlafatsang e ka phekolehang ka mocheso e nang le matla a mahareng, e sebelisoang haholo ho likarolo tsa meralo joalo ka litšiea le liphanele tsa mahlakoreng ho tsamaisa matla. Kenyelletso ea limaraka tsa alloy ea aluminium e bontšoa ho Lethathamo la 1.

2.2 Extrusion ke Mokhoa oa Bohlokoa oa ho Etsa oa Aluminium Alloy

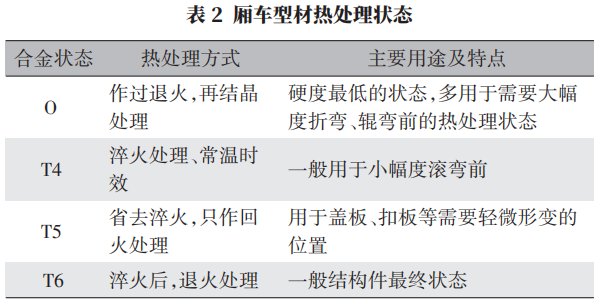

Aluminium alloy extrusion ke mokhoa o chesang oa ho theha, 'me mokhoa oohle oa tlhahiso o kenyelletsa ho etsa motsoako oa aluminium tlas'a khatello ea khatello ea mekhoa e meraro. Ts'ebetso eohle ea tlhahiso e ka hlalosoa ka tsela e latelang: a. Aluminium le lisebelisoa tse ling li qhibiliha ebe li lahleloa ka har'a li-billet tse hlokahalang tsa aluminium; b. Li-billet tse chesitsoeng pele li kenngoa ka har'a thepa ea extrusion bakeng sa extrusion. Tlas'a ketso ea cylinder e kholo, aluminium alloy billet e thehoa ka har'a litlaleho tse hlokehang ka sekoahelo sa hlobo; c. E le ho ntlafatsa thepa ea mechine ea litlaleho tsa aluminium, phekolo ea tharollo e etsoa nakong kapa ka mor'a extrusion, e lateloa ke phekolo ea botsofali. Thepa ea mechine ka mor'a phekolo ea botsofali e fapana ho ea ka lisebelisoa tse fapaneng le mebuso ea botsofali. Boemo ba kalafo ea mocheso oa liprofaele tsa literaka tsa mofuta oa lebokose bo bontšoa ho Lethathamo la 2.

Lihlahisoa tsa aluminium alloy extruded li na le melemo e mengata ho feta mekhoa e meng ea ho etsa:

a. Nakong ea extrusion, tšepe extruded fumana matla le ho feta junifomo compressive khatello ea kelello sebakeng deformation ho feta rolling le forging, kahoo e ka ka ho feletseng bapala polasetiki ea tšepe sebetswa. E ka sebelisoa ho sebetsana le litšepe tse thata-ho holofala tse ke keng tsa sebetsoa ka ho roala kapa ho fereka 'me li ka sebelisoa ho etsa likarolo tse fapaneng tse rarahaneng tse se nang letho kapa tse thata tse nang le likarolo tse fapaneng.

b. Hobane geometry ea profiles ea aluminium e ka fapana, likarolo tsa tsona li na le boima bo phahameng, bo ka ntlafatsang ho tiea ha 'mele oa koloi, ho fokotsa litšobotsi tsa eona tsa NVH, le ho ntlafatsa litšobotsi tsa taolo ea likoloi.

c. Lihlahisoa tse nang le katleho ea extrusion, ka mor'a ho tima le ho tsofala, li na le matla a longitudinal a phahameng haholo (R, Raz) ho feta lihlahisoa tse entsoeng ka mekhoa e meng.

d. Bokaholimo ba lihlahisoa ka mor'a extrusion bo na le 'mala o motle le khanyetso e ntle ea kutu, e felisang tlhoko ea kalafo e meng ea anti-corrosion.

e. Ts'ebetso ea Extrusion e na le phetoho e kholo, lisebelisoa tse tlase le litšenyehelo tsa hlobo, le litšenyehelo tse tlase tsa phetoho ea moralo.

f. Ka lebaka la taolo ea likarolo tse fapaneng tsa profil ea aluminium, tekanyo ea kopanyo ea likarolo e ka eketsoa, palo ea likarolo e ka fokotsoa, 'me meralo e fapaneng ea likarolo tse fapaneng e ka fihlela boemo bo nepahetseng ba welding.

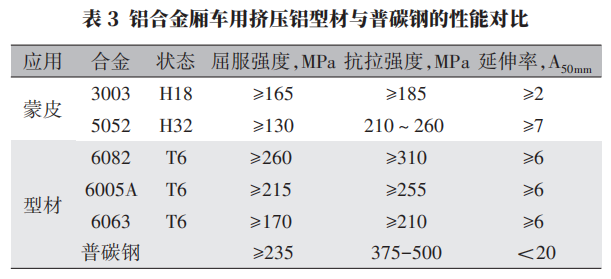

Papiso ea ts'ebetso lipakeng tsa profaele ea aluminium e extruded bakeng sa literaka tsa mofuta oa mabokose le tšepe e hlakileng ea carbon e bonts'itsoe ho Lethathamo la 3.

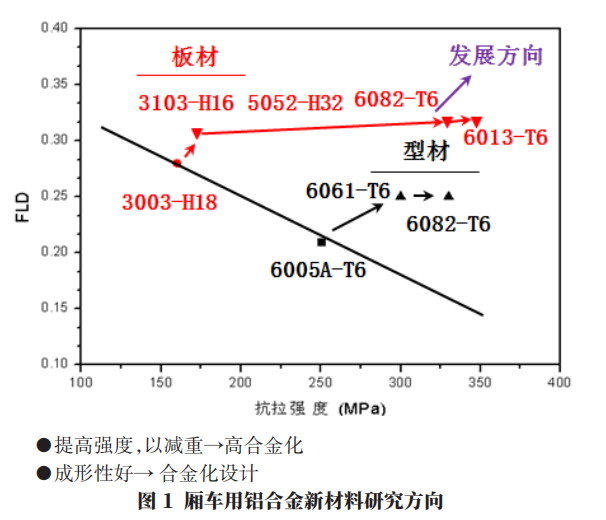

Tataiso e Latelang ea Nts'etsopele ea Aluminium Alloy Profiles bakeng sa Literaka tsa mofuta oa Lebokose: Ho ntlafatsa matla a profil le ho ntlafatsa ts'ebetso ea extrusion. Tataiso ea lipatlisiso tsa lisebelisoa tse ncha bakeng sa profil ea alloy ea aluminium bakeng sa literaka tsa mofuta oa mabokose e bonts'itsoe ho Setšoantšo sa 1.

3.Aluminium Alloy Box Truck Structure, Matla Analysis, le netefatso

3.1 Sebopeho sa Aluminium Alloy Box Truck

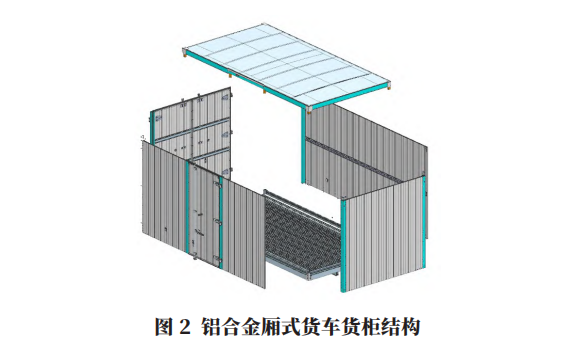

Lebokose la teraka ea teraka haholo-holo le na le kopano ea phanele e ka pele, kopano ea lehlakore le letšehali le le letona, kopano e ka morao ea lemati, kopano ea fatše, kopano ea marulelo, hammoho le liboutu tse bōpehileng joaloka U, balebeli ba mahlakoreng, balebeli ba ka morao, liphahlo tsa seretse, le lisebelisoa tse ling tse amanang le mochine oa bobeli oa sehlopha. Lebokose la maballo a 'mele, litšiea, maballo a mahlakoreng le liphanele tsa mamati li entsoe ka li-profiles tsa aluminium alloy extruded, ha mokatong le marulelong li entsoe ka lipoleiti tse 5052 tsa aluminium alloy. Sebopeho sa teraka ea aluminium alloy box se bontšoa setšoantšong sa 2.

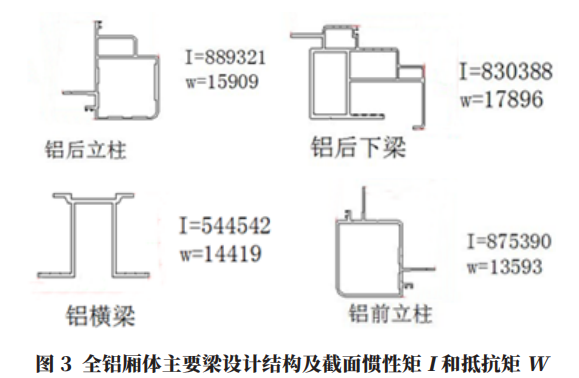

Ho sebelisa ts'ebetso e chesang ea extrusion ea 6 letoto la aluminium alloy e ka etsa likarolo tse rarahaneng tse se nang letho, moralo oa li-profiles tsa aluminium tse nang le likarolo tse rarahaneng tse fapaneng li ka boloka lisebelisoa, tsa fihlela litlhoko tsa matla a sehlahisoa le ho satalla, 'me tsa fihlela litlhoko tsa khokahano e kopanetsoeng lipakeng tsa likarolo tse fapaneng. Ka hona, sebopeho se seholo sa boqapi le linako tsa inertia I le linako tsa ho hanyetsa W li bonts'itsoe ho Setšoantšo sa 3.

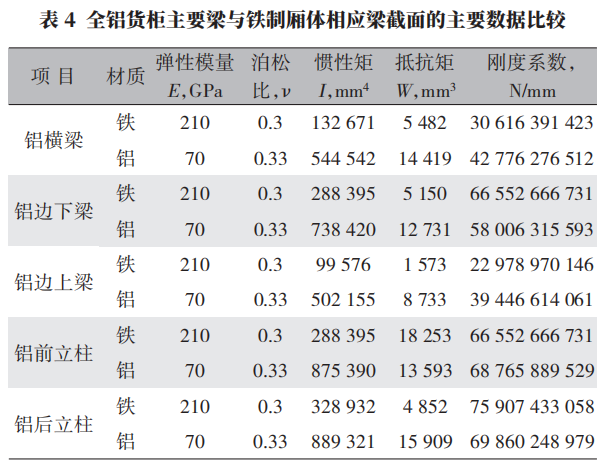

Papiso ea lintlha tse ka sehloohong ho Lethathamo la 4 e bontša hore nako ea likarolo tsa inertia le ho hanyetsa nako ea profil e entsoeng ka aluminium e molemo ho feta lintlha tse lumellanang tsa profil ea tšepe e entsoeng ka tšepe. Lintlha tsa coefficient tsa ho satalla li batla li tšoana le tsa profil e tsamaellanang ea tšepe e entsoeng ka tšepe, 'me kaofela li fihlela litlhoko tsa deformation.

3.2 Palo e kholo ea khatello ea maikutlo

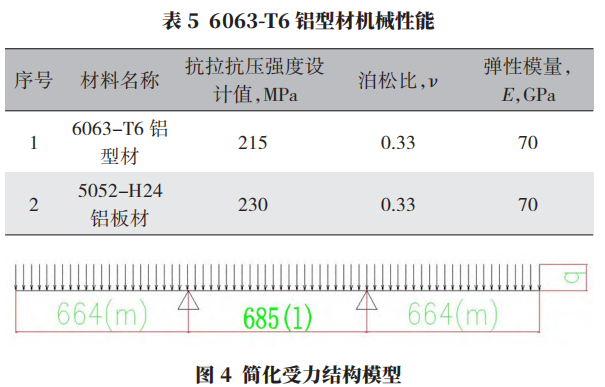

Ho nka karolo ea bohlokoa ea mojaro, crossbeam, e le ntho, khatello e phahameng ea khatello e baloa. Moroalo o lekantsoeng ke 1.5 t, 'me crossbeam e entsoe ka profil ea aluminium ea 6063-T6 e nang le lisebelisoa tsa mechine joalokaha ho bontšitsoe Lethathamong la 5. Sefate se nolofalitsoe e le sebopeho sa cantilever bakeng sa ho bala matla, joalokaha ho bontšitsoe setšoantšong sa 4.

Ho nka sephara sa span ea 344mm, mojaro o hatellang holim'a sefate o baloa e le F = 3757 N e thehiloeng ho 4.5t, e leng makhetlo a mararo ho feta mojaro o tloaelehileng. q=F/L

moo q e leng khatello ea ka hare ea leballo tlas'a mojaro, N / mm; F ke mojaro o jereng sefate, o baloang ho latela makhetlo a 3 boima bo tloaelehileng, e leng 4.5 t; L ke bolelele ba leballo, mm.

Ka hona, khatello ea kelello q ke:

Foromo ea ho bala khatello ea maikutlo ke e latelang:

Nako e kholo ke:

Ho nka boleng bo feletseng ba motsotso, M=274283 N·mm, khatello e kholo ea σ=M/(1.05×w)=18.78 MPa, le khatello e phahameng ea khatello σ<215 MPa, e finyellang litlhoko.

3.3 Litšobotsi tsa Khokahano ea Likarolo tse fapaneng

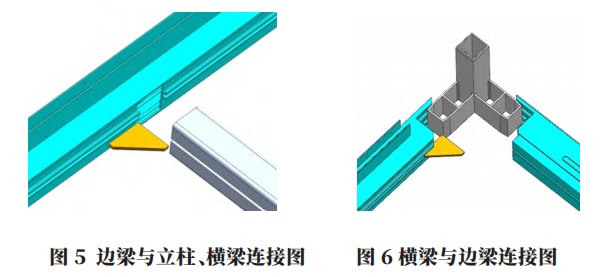

Aluminium alloy e na le thepa e fokolang ea ho cheselletsa, 'me matla a eona a ho cheselletsa ke 60% feela ea matla a thepa ea motheo. Ka lebaka la ho koaheloa ha lera la Al2O3 holim'a aluminium alloy surface, sebaka se qhibilihisang sa Al2O3 se phahame, ha sebaka sa ho qhibiliha sa aluminium se tlaase. Ha aluminium alloy e cheselitsoe, Al2O3 e holim'a metsi e tlameha ho robeha kapele ho etsa welding. Ka nako e ts'oanang, masala a Al2O3 a tla lula a le tharollo ea aluminium alloy, e amang sebopeho sa motsoako oa aluminium le ho fokotsa matla a ntlha ea aluminium alloy welding. Ka hona, ha ho etsoa setshelo sa aluminium kaofela, litšobotsi tsena li nahanoa ka botlalo. Welding ke mokhoa o ka sehloohong oa ho beha maemo, 'me likarolo tse ka sehloohong tse jarang moroalo li hokahane ka liboutu. Lihokelo tse joalo ka sebopeho sa riveting le dovetail li bonts'itsoe ho Lipalo 5 le 6.

Mohaho o ka sehloohong oa 'mele oa lebokose la aluminium kaofela o amohela sebopeho se nang le maballo a rapameng, litšiea tse emeng, maballo a mahlakoreng, le maballo a mathōko a hokahaneng. Ho na le lintlha tse 'nè tsa khokahanyo pakeng tsa leballo le leng le le leng le tšekaletseng le tšiea e emeng. Lintlha tsa ho hokahanya li kentsoe li-gaskets tse serrated ho etsa mesh le moeli o serrated oa sebanka se otlolohileng, ka nepo ho thibela ho thella. Likarolo tse robeli tsa likhutlo li kopantsoe haholo ke lisebelisoa tsa mantlha tsa tšepe, tse tsitsitseng ka li-bolts le li-rivets tse itšebetsang, 'me li matlafalitsoe ke lipoleiti tsa aluminium tse 5mm tse tharo tse cheselitsoeng ka har'a lebokose ho matlafatsa maemo a sekhutlo ka hare. Ponahalo ea ka ntle ea lebokose ha e na li-welding kapa lintlha tsa khokahanyo tse pepenene, ho netefatsa ponahalo ea kakaretso ea lebokose.

3.4 SE Synchronous Engineering Technology

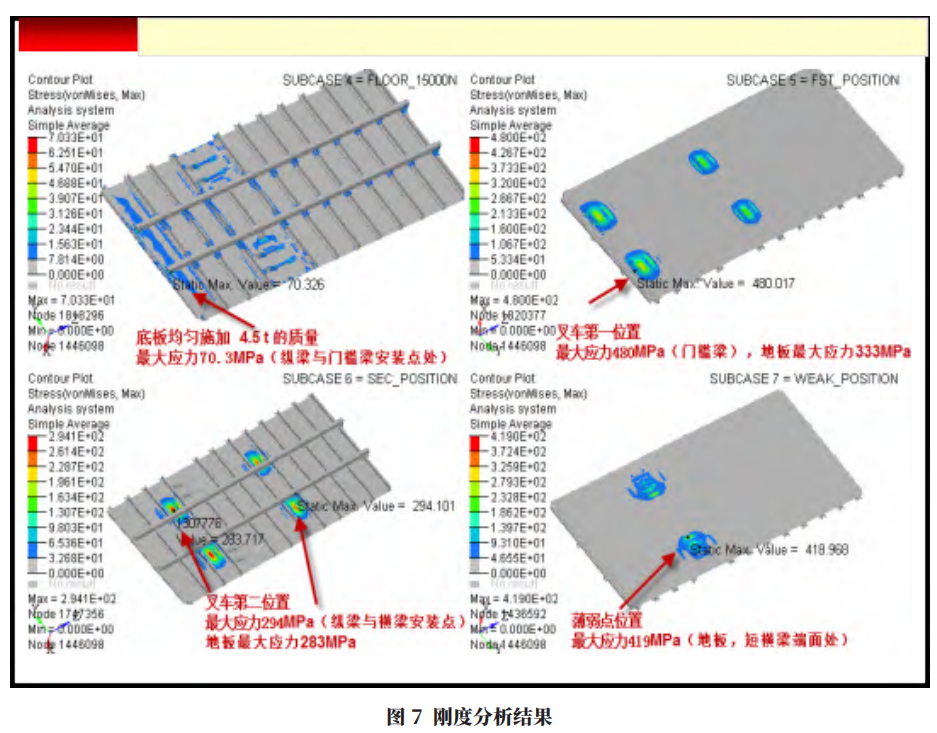

Theknoloji ea boenjiniere ea SE synchronous e sebelisoa ho rarolla mathata a bakoang ke ho kheloha ho hoholo ha boholo bo bokelletsoeng bakeng sa likarolo tse lekanang ka har'a lebokose la 'mele le mathata a ho fumana lisosa tsa likheo le ho hloleha ha botenya. Ka tlhahlobo ea CAE (bona Setšoantšo sa 7-8), tlhahlobo ea papiso e etsoa le lihlopha tse entsoeng ka tšepe tse entsoeng ka tšepe ho hlahloba matla a kakaretso le boima ba 'mele oa lebokose, ho fumana lintlha tse fokolang, le ho nka mehato ea ho ntlafatsa le ho ntlafatsa moralo oa moralo ka katleho.

4.Lightweighting Effect ea Aluminium Alloy Box Truck

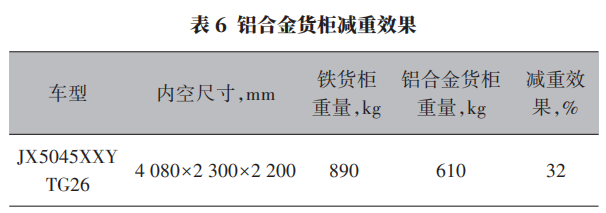

Ntle le 'mele oa lebokose, lisebelisoa tsa aluminium li ka sebelisoa ho nkela tšepe bakeng sa likarolo tse fapaneng tsa lijana tsa literaka tsa mofuta oa mabokose, joalo ka balebeli ba seretse, balebeli ba ka morao, balebeli ba mahlakoreng, lithapo tsa mamati, lihokelo tsa mamati le methati ea apron e ka morao, ho fokotsa boima ba 30% ho isa ho 40% bakeng sa phaposi ea thepa. Phello ea ho fokotsa boima ba 'mele bakeng sa sejana sa thepa ea 4080mm×2300mm×2200mm e se nang letho e bontšoa ho Lethathamo la 6. Sena se rarolla mathata a boima bo feteletseng, ho se lumellane le liphatlalatso, le likotsi tsa taolo ea likarolo tsa thepa tse tloaelehileng tse entsoeng ka tšepe.

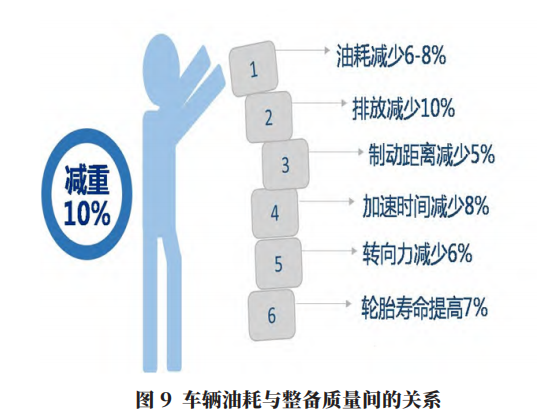

Ka ho nkela tšepe ea setso sebaka ka lisebelisoa tsa aluminium bakeng sa likarolo tsa likoloi, ha se feela hore ho ka fihleloa litlamorao tse ntle tsa ho fokotsa boima ba 'mele, empa hape ho ka kenya letsoho ho bolokeng mafura, ho fokotsa mosi le ho ntlafatsa ts'ebetso ea koloi. Hona joale, ho na le maikutlo a sa tšoaneng mabapi le monehelo oa ho fokotsa boima ba 'mele ho boloka mafura. Liphetho tsa lipatlisiso tsa International Aluminium Institute li bontšoa ho Setšoantšo sa 9. Phokotso e 'ngoe le e' ngoe ea 10% ea boima ba koloi e ka fokotsa tšebeliso ea mafura ka 6% ho 8%. Ho itšetlehile ka lipalo-palo tsa malapeng, ho fokotsa boima ba koloi e 'ngoe le e' ngoe ea baeti ka lik'hilograma tse 100 ho ka fokotsa tšebeliso ea mafura ka 0.4 L / 100 km. Tlatsetso ea ho fokotsa boima ba 'mele ho boloka mafura e ipapisitse le liphetho tse fumanoeng mekhoeng e fapaneng ea lipatlisiso, kahoo ho na le phapang e itseng. Leha ho le joalo, khanya ea likoloi e na le phello e kholo ho fokotsa tšebeliso ea mafura.

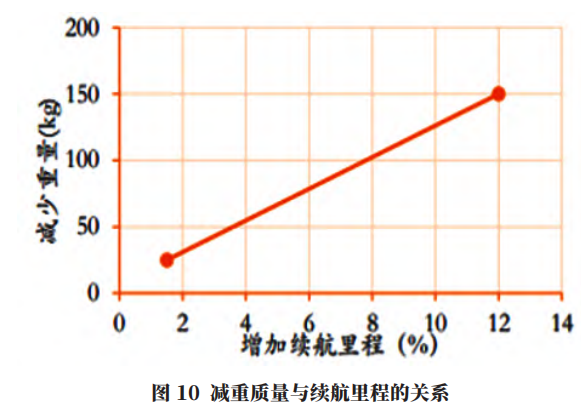

Bakeng sa likoloi tsa motlakase, phello e bobebe e bonahala le ho feta. Hajoale, matla a yuniti a betri ea motlakase oa koloi a fapane haholo le a likoloi tsa khale tsa mafura a mokelikeli. Boima ba tsamaiso ea matla (ho kenyeletsoa le betri) ea likoloi tsa motlakase hangata li nka 20% ho 30% ea boima ba koloi kaofela. Ka nako e ts'oanang, ho senya bothata ba betri ke phephetso ea lefats'e ka bophara. Pele ho e-ba le katleho e kholo ea theknoloji ea betri e sebetsang hantle, ho fokotsa boima ba 'mele ke mokhoa o atlehang oa ho ntlafatsa mefuta e mengata ea likoloi tsa motlakase. Bakeng sa phokotso e 'ngoe le e' ngoe ea boima ba lik'hilograma tse 100, lebelo la likoloi tsa motlakase le ka eketsoa ka 6% ho ea ho 11% (kamano pakeng tsa ho fokotsa boima ba 'mele le ho tsamaea ka sekepe ho bontšoa ho Setšoantšo sa 10). Hona joale, mefuta e mengata ea likoloi tsa motlakase e hloekileng e ke ke ea finyella litlhoko tsa batho ba bangata, empa ho fokotsa boima ba 'mele ka tekanyo e itseng ho ka ntlafatsa haholo sebaka sa ho tsamaea, ho fokotsa matšoenyeho le ho ntlafatsa phihlelo ea mosebedisi.

5.Qetello

Ntle le sebopeho sa aluminium kaofela sa teraka ea aluminium alloy box e hlahisitsoeng sehloohong sena, ho na le mefuta e fapaneng ea literaka tsa mabokose, joalo ka liphanele tsa mahe a linotši tsa aluminium, lipoleiti tsa aluminium, liforeimi tsa aluminium + matlalo a aluminium, le lijana tsa thepa tse nyalisitsoeng tsa tšepe-aluminium. Li na le melemo ea boima bo bobebe, matla a khethehileng a phahameng, 'me ha li hloke pente ea electrophoretic bakeng sa tšireletso ea ho senya, ho fokotsa tšusumetso ea tikoloho ea pente ea electrophoretic. Lori ea aluminium alloy box e rarolla mathata a boima bo feteletseng, ho se ikobele liphatlalatso, le likotsi tsa taolo ea likarolo tsa thepa tse entsoeng ka tšepe tse tloaelehileng.

Extrusion ke mokhoa oa bohlokoa oa ho sebetsana le li-alloys tsa aluminium, 'me li-profiles tsa aluminium li na le thepa e ntle ea mochine, kahoo ho satalla ha karolo ea likarolo ho batla ho phahame. Ka lebaka la likarolo tse fapaneng tsa li-cross-section, li-alloys tsa aluminium li ka finyella motsoako oa likarolo tse ngata tsa likarolo, e leng se etsang hore e be thepa e ntle bakeng sa ho bonesa likoloi. Leha ho le joalo, ts'ebeliso e atileng ea li-alloys tsa aluminium e tobane le liphephetso tse kang bokhoni bo sa lekaneng ba moralo bakeng sa likarolo tsa thepa ea alloy alloy, litaba tsa ho theha le ho tjheseletsa, le litšenyehelo tse phahameng tsa nts'etsopele le nts'etsopele ea lihlahisoa tse ncha. Lebaka le ka sehloohong e ntse e le hore alloy alloy e bitsa chelete e ngata ho feta tšepe pele ho tsosolosoa ha lisebelisoa tsa aluminium ho hōla.

Qetellong, sebaka sa ts'ebeliso ea li-alloys tsa aluminium likoloing se tla pharalla, 'me ts'ebeliso ea tsona e tla tsoela pele ho eketseha. Mekhoeng ea hajoale ea ho boloka matla, phokotso ea tlhahiso, le nts'etsopele ea indasteri e ncha ea likoloi tsa matla, ka kutloisiso e tebileng ea thepa ea aluminium alloy le tharollo e sebetsang ea mathata a ts'ebeliso ea alloy aluminium, lisebelisoa tsa aluminium extrusion li tla sebelisoa haholo ho bobebe ba likoloi.

E hlophisitsoeng ke May Jiang ho tsoa ho MAT Aluminium

Nako ea poso: Jan-12-2024