1. Litšobotsi tsa aluminium le aluminium motsoako o khethehileng lisebelisoa tsa extrusion tse nepahetseng

Mofuta ona oa sehlahisoa o na le sebopeho se khethehileng, botenya ba lerako le tšesaane, boima ba yuniti e bobebe, le litlhoko tse thata haholo tsa mamello. Lihlahisoa tse joalo hangata li bitsoa aluminium alloy precision (kapa ultra-precision) profiles (liphaephe), 'me theknoloji ea ho hlahisa lihlahisoa tse joalo e bitsoa ho nepahala. (or ultra-precision) extrusion.

Likarolo tsa mantlha tsa li-extrusions tsa aluminium alloy ka mokhoa o khethehileng (kapa o nepahetseng haholo) ke:

(1) Ho na le mefuta e mengata, lihlopha tse nyenyane, 'me boholo ba tsona ke lisebelisoa tse khethehileng tsa extrusion, tse sebelisoang hoo e batlang e le likarolong tsohle tsa bophelo le likarolong tsohle tsa bophelo ba batho, ho akarelletsa le lihlahisoa tsohle tsa extrusion, tse kang liphaephe, mekoallo, profiles le lithapo, tse kenyelletsang motsoako o sa tšoaneng le naha. Ka lebaka la likaroloana tse nyenyane tsa sefapano, botenya ba lebota le lesesaane, boima bo bobebe, le lihlopha tse nyenyane, ka kakaretso ha ho bonolo ho hlophisa tlhahiso.

2 Sebaka se ka holimo ho boholo ba yuniti se seholo, 'me theknoloji ea tlhahiso e thata.

(3) Ts'ebeliso e pharaletseng, ts'ebetso e khethehileng le litlhoko tsa ts'ebetso. E le ho finyella litlhoko tsa tšebeliso ea sehlahisoa, linaha tse ngata tsa alloy li khethiloe, tse koahelang hoo e batlang e le li-alloys tsohle ho tloha ho 1 × × ho ea ho 8 × × letoto le likarolo tse ngata tsa phekolo, tse nang le litaba tse phahameng tsa theknoloji.

(4) Ponahalo e tsotehang le botenya ba lerako le tšesaane, ka kakaretso e ka tlaase ho 0.5mm, ba bang ba bile ba fihla hoo e ka bang 0.1mm, boima ka mithara ke ligrama tse seng kae ho isa ho mashome a ligrama, empa bolelele bo ka fihla ho limithara tse 'maloa, kapa esita le limithara tse makholo.

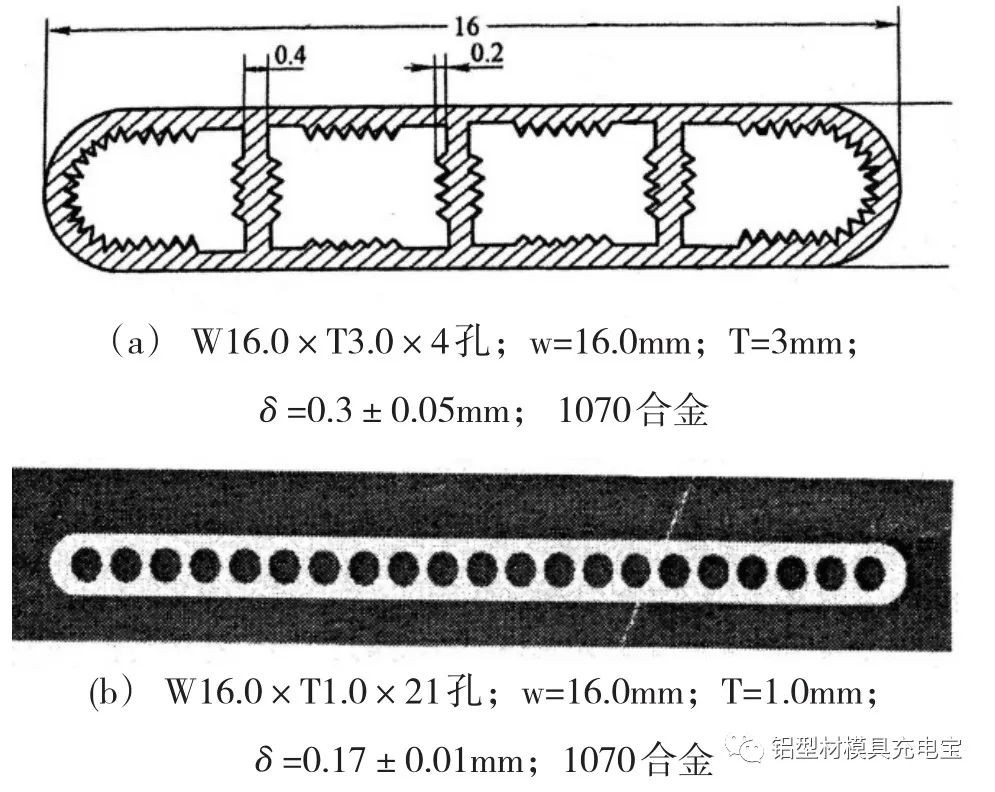

5) Ho nepahala ha dimensional le litlhoko tsa mamello ea geometri tsa karolo li thata haholo. Ka kakaretso, mamello ea liprofaele tse nepahetseng tsa aluminium alloy e matla ho feta habeli ho feta mamello e khethehileng ea maemo a JIS, GB le ASTM. Mamello ea botenya ba lebota ea li-profiles tsa alloy tsa aluminium tse nepahetseng ka kakaretso e tlameha ho ba pakeng tsa ± 0.04mm le 0.07mm, athe mamello ea boholo ba karolo ea liprofaele tsa alloy ea aluminium e ka bang ± 0.01mm. Ka mohlala, boima ba profil ea aluminium e nepahetseng e sebelisetsoang potentiometer ke 30g / m, 'me tekanyo ea mamello ea boholo ba karolo ke ± 0.07mm. Mamello ea boholo ba likarolo tse fapaneng tsa profiles tse nepahetseng tsa aluminium bakeng sa looms ke ± 0.04mm, ho kheloha ha angle ho ka tlase ho 0.5 °, 'me tekanyo ea ho kobeha ke 0.83×L. Mohlala o mong ke phaephe e pharalletseng e tšesaane e phahameng haholo bakeng sa likoloi, e bophara ba 20mm, bolelele ba 1.7mm, botenya ba lerako ba 0.17±0.01mm, le masoba a 24, e leng lintlha tse tloaelehileng tsa aluminium alloy profiles.

(6) E na le litaba tse phahameng tsa theknoloji 'me e thata haholo ho e hlahisa,' me e na le litlhoko tse khethehileng tsa lisebelisoa tsa extrusion, lisebelisoa, li-billet le mekhoa ea tlhahiso. Setšoantšo sa 1 ke mohlala oa karolo ea li-profiles tse nyane tse nepahetseng tsa aluminium alloy.

2. Sehlopha sa aluminium motsoako o khethehileng lisebelisoa tsa extrusion tse nepahetseng

Precision kapa ultra-precision aluminium alloy extrusions li sebelisoa haholo ka lisebelisoa tsa elektroniki, lisebelisoa tsa puisano le mahlale a morao-rao, ts'ireletso ea naha le indasteri ea sesole, lisebelisoa tse nepahetseng tsa mochini, lisebelisoa tse fokolang tsa hajoale, sefofane, indasteri ea nyutlelie, matla le matla, likepe tse tsamaeang ka tlas'a metsi le likepe, likoloi le lisebelisoa tsa lipalangoang, lisebelisoa tsa bongaka, lisebelisoa tsa Hardware, mabone, ho nka lifoto le lisebelisoa tsa elektroniki. Ka kakaretso, li-extrusions tsa alloy tsa aluminium tse nepahetseng kapa tse nepahetseng ka ho fetesisa li ka aroloa ka mekhahlelo e 'meli ho latela litšobotsi tsa bona tsa ponahalo: sehlopha sa pele ke lintlha tse nang le litekanyo tse nyane. Mofuta ona oa profil o boetse o bitsoa "ultra-small profile" kapa "mini-shape". Boholo ba eona ka kakaretso hangata ke limilimithara tse seng kae feela, bonyane botenya ba lebota bo ka tlase ho 0.5mm, 'me boima ba yuniti ke ligrama tse' maloa ho isa ho mashome a ligrama ka mithara. Ka lebaka la boholo ba bona bo fokolang, hangata ho hlokahala mamello e thata ho bona. Ka mohlala, mamello ea litekanyo tsa li-cross-sectional e ka tlase ho ± 0.05mm. Ho phaella moo, litlhoko tsa ho otloloha le torsion ea lihlahisoa tse extruded le tsona li thata haholo.

Mofuta o mong ke oa li-profiles tse seng nyane haholo ka boholo ba likarolo tse fapaneng empa li hloka mamello e thata haholo ea li-dimensional, kapa li-profile tse nang le sebopeho se rarahaneng sa likarolo le botenya ba lerako le lesesaane le hoja boholo ba likarolo li le kholo. Setšoantšo sa 2 se bonts'a tube e nang le sebōpeho se khethehileng (aluminium e hloekileng ea indasteri) e fetisitsoeng ke k'hamphani ea Majapane ka mochine oa khatiso oa hydraulic o nang le 16.3MN o nang le mochine o khethehileng oa ho arohana bakeng sa condenser ea moea oa koloi. Bothata ba ho etsa extrusion ea mofuta ona oa profil ha bo tlase ho feta ba mofuta oa pele oa profil e nyane haholo. Li-profile tse atolositsoeng tse nang le boholo ba karolo e kholo le litlhoko tse thata tsa mamello ha li hloke feela theknoloji e tsoetseng pele ea moralo oa hlobo, empa hape li hloka theknoloji e thata ea taolo bakeng sa ts'ebetso eohle ea tlhahiso ho tloha ho sekheo ho isa sehlahisoa se felileng.

Ho tloha mathoasong a lilemo tsa bo-1980, ka lebaka la ts'ebeliso e sebetsang ea Conform continuous extrusion technology le nts'etsopele ea thekenoloji ea indasteri, extrusion ea litlaleho tse nyenyane le tse nyenyane haholo li tsoetse pele ka potlako. Leha ho le joalo, ka lebaka la mabaka a fapaneng a kang mefokolo ea thepa, litlhoko tsa boleng ba sehlahisoa, le tsoelo-pele ea theknoloji ea extrusion, tlhahiso ea litlaleho tse nyenyane ka thepa e tloaelehileng ea extrusion e ntse e ikarabella ka karolo e kholo. Setšoantšo sa 2 se bontša lintlha tse nepahetseng tsa extrusion ea ho arohana ho tloaelehileng ho shoa. Bophelo ba hlobo (haholo-holo matla le ho apara ho hanyetsa ha borokho ba shunt le mokokotlo oa hlobo) le phallo ea thepa nakong ea extrusion e fetoha lintlha tse ka sehloohong tse amang tlhahiso ea eona. Sena ke hobane ha extruding profil, boholo ba hlobo konokono e nyenyane 'me sebopeho e rarahane,' me matla le ho apara ho hanyetsa ke lintlha tsa bohlokoa tse amang bophelo ba hlobo, bophelo ba hlobo bo ama ka ho toba litšenyehelo tsa tlhahiso. Ka lehlakoreng le leng, litlaleho tse ngata tse nepahetseng li na le marako a tšesaane le libopeho tse rarahaneng, 'me ho phalla ha thepa nakong ea ts'ebetso ea extrusion ho ama ka ho toba sebopeho le ho nepahala ha likarolo.

E le ho thibela filimi ea oxide le oli holim'a billet hore e se ke ea phalla ka har'a sehlahisoa le ho etsa bonnete ba hore boleng ba junifomo le bo ka tšeptjoang ba sehlahisoa, billet e futhumetseng ho ea mocheso o behiloeng e ka ebola pele ho extrusion (e bitsoang peeling e chesang), ebe e kenngoa ka potlako ka har'a moqomo oa extrusion bakeng sa extrusion. Ka nako e ts'oanang, gasket ea extruded e lokela ho bolokoa e hloekile ho thibela oli le litšila ho khomarela gasket nakong ea ts'ebetso ea ho tlosa khatello e feteletseng ka mor'a extrusion e le 'ngoe le ho kenya gasket ka extrusion e latelang.

Ho ea ka ho nepahala ha karolo ea likarolo le sebopeho le mamello ea boemo, extrusion e khethehileng ea aluminium alloy extrusion e ka aroloa ka li-profiles tsa alloy tse khethehileng tse nepahetseng le tse nyenyane (tse nyenyane) tse phahameng ka ho fetisisa tse phahameng tsa aluminium alloy profiles. Ka kakaretso, ho nepahala ha eona ho feta maemo a naha (joalo ka GB, JIS, ASTM, joalo-joalo) ho nepahala ha ultra-high ho bitsoa li-profiles tse khethehileng tsa aluminium alloy, mohlala, mamello ea dimensional e ka holimo ho ± 0.1mm, ho mamellana ha lerako la sebaka se robehileng ho ka hare ho ± 0.05mm ~ ± 0.03mm profiles.

Ha ho nepahala ha eona ho feta habeli boemo ba naha bo phahameng ka ho fetesisa, bo bitsoa profil e nyane (e nyane) ea aluminium ea boleng bo holimo, joalo ka mamello ea sebopeho sa ± 0.09mm, mamello ea lerako la ± 0.03mm ~ ± 0.01mm bakeng sa profil e nyane (e nyane) kapa phala.

3. Litebello tsa nts'etsopele ea aluminium le alloy alloy e khethehileng lisebelisoa tsa extrusion tse nepahetseng

Ka selemo sa 2017, tlhahiso le thekiso ea lisebelisoa tsa ho sebetsa tsa aluminium lefatšeng li feta 6000kt / a, eo tlhahiso le thekiso ea thepa ea aluminium le aluminium alloy extrusion e fetang 25000kt / a, e ikarabellang ho feta 40% ea kakaretso ea tlhahiso le thekiso ea aluminium. Aluminium extruded mahareng mekoallo ikarabella bakeng sa 90%, eo profiles kakaretso le mekoallo le tse nyenyane le tse mahareng-boholo bo lekaneng kaho ea sechaba Profiles ikarabella ho feta 80% ea bareng, e khōlō le e mahareng-boholo bo lekaneng Profiles le diporofeele khethehileng khethehileng le mekoallo ikarabella ka 15% feela. Phaephe e etsa hoo e ka bang 8% ea aluminium alloy extruded material, ha phala e bōpehileng le tlaleho e khethehileng ea phala e ka bang 20% feela ea phala. Ho ka bonoa ho tsoa ka holimo hore tlhahiso e kholo ka ho fetisisa le thekiso ea lisebelisoa tsa aluminium le aluminium alloy extrusion le tse sebelisoang ka ho fetisisa ke litlaleho tse nyenyane le tse mahareng tsa mohaho oa sechaba, litlaleho tse akaretsang le mekoallo le liphaephe. 'Me litlaleho tse khethehileng, mekoallo le liphaephe li ikarabella feela hoo e ka bang 15%, litšobotsi tse ka sehloohong tsa lihlahisoa tse joalo ke: ka mesebetsi e khethehileng kapa ts'ebetso; E inehetseng molemong o itseng; Ho ba le boholo bo boholo kapa bo bonyenyane ba litlhaloso; Ka ho nepahala ho phahameng haholo kapa litlhoko tsa bokaholimo. Ka hona, mefuta e mengata e mengata 'me sehlopha se fokotsehile, tlhokahalo ea ho eketsa lits'ebetso tse khethehileng kapa ho eketsa lisebelisoa tse khethehileng le lisebelisoa, tlhahiso e thata le litaba tsa tekheniki li phahame, theko ea tlhahiso ea eketseha le boleng bo eketsehileng bo eketseha.

Ka tsoelo-pele ea saense le thekenoloji le ntlafatso e tsoelang pele ea maemo a bophelo ba batho, litlhoko tse phahameng le tse phahameng li behiloe pele bakeng sa tlhahiso, boleng le mefuta e sa tšoaneng ea lihlahisoa tsa aluminium le aluminium alloy extrusion, haholo-holo lilemong tsa morao tjena, ho hlaha ha lihlahisoa tsa motho ka mong ho khothalelitse nts'etsopele ea litlaleho tse khethehileng le liphaephe tse nang le litšobotsi tsa motho ka mong le tšebeliso e khethehileng.

Li-profile tsa Ultra-precision li sebelisoa haholo lisebelisoa tsa elektronike, puisano, poso le lisebelisoa tsa puisano, mechine e nepahetseng, lisebelisoa tse nepahetseng, lisebelisoa tse fokolang tsa hona joale, sefofane, likepe tsa nyutlelie le likepe, indasteri ea likoloi le likarolo tse ling tsa lerako le lenyenyane, le lesesaane, boholo ba karolo ea likarolo tse nepahetseng haholo. Hangata litlhoko tsa mamello li thata haholo, ka mohlala, mamello ea boholo ba karolo ea karolo e ka tlaase ho ± 0.10mm, mamello ea lerako e ka tlaase ho ± 0.05mm. Ho phaella moo, ho bata, ho sotha le mefuta e meng le mamello ea boemo ba lihlahisoa tse extruded le tsona li thata haholo. Ntle le moo, ts'ebetsong ea extrusion ea li-profiles tse nyane tse khethehileng tsa aluminium alloy, lisebelisoa, hlobo, ts'ebetso ke litlhoko tse thata haholo. Ka lebaka la nts'etsopele e potlakileng ea indasteri ea sejoale-joale, ts'ireletso ea naha le lipatlisiso tsa mahlale le mesebetsi e meng le ntlafatso ea boemo ba motho ka mong, palo, mefuta e fapaneng le boleng ba liprofinse tse nyane tse nepahetseng haholo li ntse li eketseha, le hoja lilemong tsa morao tjena, li ntlafalitse le ho hlahisa lihlahisoa tse ngata tsa boleng bo phahameng tse nyenyane tsa aluminium alloy, empa li ntse li sa khone ho finyella litlhoko tse khethehileng tsa thepa ea thepa ea malapeng. ea li-profiles tse nyane tsa aluminium alloy tse nyane tse nepahetseng haholo le boemo bo tsoetseng pele ba machabeng, bo ke keng ba khahlametsa tlhokahalo ea mmaraka ea lapeng le kantle mme e tlameha ho ts'oaroa.

4. Qetello

Aluminium le aluminium motsoako o khethehileng ka ho nepahetseng extrusion (profiles le liphaephe) ke mofuta oa sebopeho rarahaneng, tšesaane lerako botenya, mamello dimensional le sebopeho le maemo a ho nepahala ditlhoko ba batla haholo, phahameng botekgeniki dikahare, thata tlhahiso ea phahameng, thepa e ntle, ke moruo oa naha le tshireletso ya naha disebediswa tsa bohlokoa haholo, mefuta e fapaneng ya ditshebediso, solofetsang ntshetsopele ya lintho tse bonahalang tebello ea. Tlhahiso ea sehlahisoa sena e na le litlhoko tse khethehileng bakeng sa lisebelisoa tsa billet, lisebelisoa le lisebelisoa tsa extrusion le ts'ebetso ea extrusion, 'me letoto la mathata a bohlokoa a tekheniki a tlameha ho rarolloa e le ho fumana lihlahisoa tse babatsehang ka lihlopha.

E hlophisitsoeng ke May Jiang ho tsoa ho MAT Aluminium

Nako ea poso: Apr-07-2024