'Mele oa koloi o entsoeng ka thepa ea profil ea aluminium ea indasteri o na le melemo ea boima bo bobebe, ho hanyetsa kutu, ponahalo e ntle ea sebopeho se bataletseng le lisebelisoa tse ka sebelisoang hape, ka hona, o ratoa ke lik'hamphani tsa lipalangoang tsa litoropo le mafapha a lipalangoang lefatšeng ka bophara.

Mekhatlo ea likoloi tsa aluminium ea indasteri e na le mesebetsi e ke keng ea fetoha ha ho etsoa seporo sa lebelo le phahameng, kahoo lebelo la eona la nts'etsopele le potlakile haholo. Hajoale, likoloi tsa li-aluminium tsa indasteri tse nang le sebopeho sa aluminium kaofela li 'nile tsa sebelisoa haholo ha ho etsoa li-EMU le likoloi tsa literene tsa litoropong, haholo-holo mehaho ea tšepe ea li-EMU tsa lebelo le phahameng kaofela li nkeloa sebaka ke mekhatlo ea likoloi tsa aluminium tsa indasteri.

Ts'ebetsong ea tlhahiso ea likoloi tsa likoloi tsa liindasteri tsa aluminium, ka lebaka la ts'ebeliso e pharaletseng ea profil splicing mohahong, 'me manonyeletso a nako e telele ebile a tloaelehile, e leng se loketseng bakeng sa ho phethahatsa ts'ebetso ea othomathike, kahoo mekhoa e fapaneng ea theknoloji ea ho tjheseletsa e sebelisoa haholo indastering ena.

Lefapha la likoloi tsa aluminium tsa indasteri (Mohloli: Asia Finance)

Ho tjheseletsa ka othomathike ho nka maemo a bohlokwa ho tjheseletsa ha mekgatlo ya makoloi a aluminium ya indasteri. E 'nile ea tsejoa ka ho pharaletseng ke lik'hamphani tsa welding bakeng sa melemo ea eona ea boleng bo tsitsitseng ba ho tjheseletsa le katleho e phahameng ea tlhahiso. Hona joale ha tlhokahalo tšimong ea ho cheselletsa ka bohlale e ntse e eketseha haholo, ho lumeloa hore theknoloji ea welding e tla ntlafatsoa haholo nakong e tlang e haufi.

Litšobotsi tsa sebopeho sa 'mele oa likoloi tsa aluminium tsa indasteri bakeng sa li-EMU tse lebelo le holimo

Sehlopha sa likoloi tsa aluminium tsa indasteri tsa li-EMU tse lebelo le phahameng li arotsoe haholo ka sehlopha sa likoloi tsa aluminium tsa indasteri le sehlopha sa koloi ea hlooho ea profil ea aluminium ea indasteri. Sehlopha sa mahareng sa koloi sa profil ea aluminium ea indasteri se entsoe haholo ka likarolo tse 'ne: underframe, lebota le lehlakoreng, marulelo le lerako la ho qetela. 'Mele oa koloi ea hlooho ea profil ea aluminium ea indasteri e entsoe haholo ka likarolo tse hlano: underframe, lebota le lehlakoreng, marulelo, lerako la ho qetela le ka pele.

Ts'ebeliso ea theknoloji ea welding ea MIG ea othomathike ha ho etsoa mekhatlo ea makoloi a aluminium ea liindasteri bakeng sa li-EMU tse lebelo le holimo.

Ho chesetsoa ha profil ea aluminium ea indasteri ea 'mele oa likoloi ho li-EMU tse lebelo le phahameng hangata li arotsoe ka li-welding tsa likarolo tse kholo, likarolo tse nyane le kopano e akaretsang. Ho tjheseletsa ka tsela e iketsang ha dikarolo tse kgolo ka kakaretso ho bolela ho tjheseletsa ka ho iketsa ha diphanele tsa marulelo, diphanele tsa marulelo a bataletseng, fuluru, marulelo le mabota a mahlakoreng; Ho tjheseletsa ka othomathike ha dikarolo tse nyane ka kakaretso ho bolela ho tjheseletsa ha mabota ka bohona, mabota, mabota a karohano, lipoleiti tsa skirt le litulo tsa banyalani. The jarolla ka ho iketsa tjheseletsa ea kopano e akaretsang ka kakaretso e bua ka jarolla ka ho iketsa tjheseletsa ea manonyeletso pakeng tsa lerako lehlakoreng le marulelo, le lebota lehlakoreng le underframe. Ho tsetela ho lisebelisoa tse kholo tsa li-welding ke boemo bo hlokahalang bakeng sa ho etsa mekhatlo ea makoloi a aluminium ea indasteri.

Boemong ba pele ba tlhahiso ea li-profiles tsa aluminium tsa indasteri tsa EMU tsa lebelo le phahameng, ho ile ha sebelisoa roboto e le 'ngoe ea terata ea IGM bakeng sa welding ea othomathike. Ka katoloso ea matla a tlhahiso ea EMU le tokiso ea sebopeho sa ts'ebetso, liroboto tsa welding tsa IGM tse nang le terata e le 'ngoe li lahliloe ka lebaka la katleho ea tsona e tlase ea tlhahiso. Ho fihlela joale, likarolo tsohle tse kholo tsa likoloi tsa liindasteri tsa aluminium tsa EMU tse lebelo le holimo li entsoe ka liroboto tse peli tsa wire IGM.

Ts'ebeliso e pharalletseng ea theknoloji ea othomathike ea MIG ha ho etsoa mekhatlo ea makoloi a aluminium ea lebelo le phahameng la EMU e ntlafalitse haholo boemo ba theknoloji ea welding le bokhoni ba tlhahiso ea mohala oa tlhahiso, ka hona ho netefatsa boleng ba lihlahisoa tsa mekhatlo ea makoloi ea aluminium ea liindasteri ea lebelo le phahameng la EMU, e entse tlatsetso e ikhethang tšimong ea tlhahiso ea literene tse lebelo.

IGM tjheseletsa roboto

Tšebeliso ea Friction Stir Welding Technology ho Tlhahiso ea Likoloi tsa Aluminium tsa Indasteri 'Mele oa li-EMU tsa lebelo le phahameng.

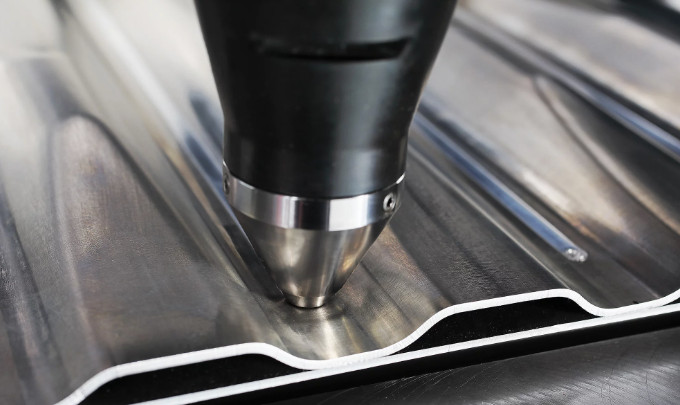

Friction Stir Welding (Mohloli: grenzebach)

Friction stir welding (FSW) ke mokhoa o tiileng oa ho kopanya. Lenonyeletso le nang le welded le na le thepa e ntle ea mochini le deformation e nyane ea welding. Ha ho hlokahale ho eketsa khase e sireletsang le terata ea welding, 'me ha ho na ho qhibiliha, lerōle, spatter le leseli la arc nakong ea ts'ebetso ea welding, e leng theknoloji e ncha ea ho kopanya tikoloho. Lilemong tse 'maloa feela ka mor'a ho fihla ha theknoloji ea FSW, ho se ho entsoe tsoelo-pele e kholo mochineng oa eona oa ho cheselletsa, lisebelisoa tse sebetsang, lisebelisoa tsa ho cheselletsa le lisebelisoa tsa boenjiniere.

E hlophisitsoeng ke May Jiang ho tsoa ho MAT Aluminium

Hlakola 15, 2023

Nako ea poso: Feb-18-2023