Patlisiso e batsi e entsoe mabapi le tlatsetso ea likarolo tse sa tloaelehang tsa lefatše (REEs) ho 7xxx, 5xxx, le 2xxx letoto la li-alloys tsa aluminium, tse bontšang litlamorao tse hlokomelehang. Haholo-holo, li-alloys tsa aluminium tse 7xxx, tse nang le likarolo tse ngata tsa alloying, hangata li ba le karohano e matla nakong ea ho qhibiliha le ho lahlela, e leng se lebisang ho thehoeng ha mekhahlelo e mengata ea eutectic. Sena se fokotsa ho tiea le ho hanyetsa kutu, ho senya ts'ebetso ea kakaretso ea alloy. Ho kenyelletsoa ha likarolo tse sa tloaelehang tsa lefats'e ka har'a li-alloys tsa aluminium tse kopantsoeng haholo ho ka ntlafatsa lijo-thollo, tsa hatella karohano, le ho hloekisa matrix, ka hona, ho ntlafatsa sebopeho sa microstructure le thepa ka kakaretso.

Haufinyane tjena, mofuta o mong oa sehloekisi sa lijo-thollo se entsoeng ka maiketsetso se se se lebisitsoe tlhokomelong. Bahloekisi bana ba sebelisa lintho tse sa tloaelehang tsa lefatše tse kang La le Ce ho matlafatsa ho fokolloa ha lijo-thollo le meeli ea lijo-thollo. Sena ha se ntlafatse lijo-thollo feela empa se boetse se khothalletsa ho hasana ho tšoanang ha li-precipitates, ho hatella recrystallization, le ho ntlafatsa haholo alloy ductility, qetellong ho eketsa tlhahiso ea mekhoa ea extrusion.

Ka 7xxx letoto la li-alloys tsa aluminium, likarolo tse sa tloaelehang tsa lefats'e hangata li eketsoa ka mekhoa e meraro:

1.Lintho tse sa tloaelehang tsa lefats'e feela;

2.Motsoako oa Zr le likarolo tse sa tloaelehang tsa lefatše;

3.Motsoako oa Zr, Cr, le likarolo tse sa tloaelehang tsa lefatše.

Kakaretso ea likarolo tse sa tloaelehang tsa lefats'e hangata li laoloa ka har'a 0.1-0.5 wt%.

Mechanis of Rare Earth Elements

Lintho tse sa tloaelehang tsa lefats'e tse kang La, Ce, Sc, Er, Gd, le Y li kenya letsoho ho li-alloys tsa aluminium ka mekhoa e mengata:

Ntlafatso ea lijo-thollo: Likarolo tse sa tloaelehang tsa lefats'e li etsa lipula tse arohaneng ka mokhoa o ts'oanang tse sebetsang e le libaka tse sa tšoaneng tsa nucleation, tse fetolang likarolo tsa dendritic hore e be lijo-thollo tse ntle tse lekanang, tse ntlafatsang matla le ductility.

Khatello ea karohano: Nakong ea ho qhibiliha le ho tiisa, likarolo tse sa tloaelehang tsa lefats'e li khothaletsa kabo ea lintho tse tšoanang, ho fokotsa sebopeho sa eutectic, le ho eketsa letsoalo la matrix.

Ho hloekisoa ha matrix: Y, La, le Ce li ka itšoara ka litšila tse qhibilihisang (O, H, N, S) ho etsa metsoako e tsitsitseng, ho fokotsa likhase tsa khase le li-inclusions, tse ntlafatsang boleng ba alloy.

Phetoho ea boits'oaro bo bocha: Likarolo tse ling tse sa tloaelehang tsa lefats'e li ka tiisa meeli ea lijo-thollo le li-subgrain, tsa thibela motsamao oa ho kheloha le ho falla ha moeli oa lijo-thollo. Sena se liehisa recrystallization le ho boloka meaho e metle ea subgrain nakong ea ts'ebetso ea mocheso, ho ntlafatsa matla le ho hanyetsa kutu.

Lintho tsa Bohlokoa tse Rare Earth le Liphello tsa tsona

Scandium (Sc)

Sc e na le radius e nyane ka ho fetisisa ea athomo har'a likarolo tse sa tloaelehang tsa lefatše hape ke tšepe ea phetoho. E sebetsa haholo ho ntlafatsa thepa ea li-alloys tsa aluminium tse holofetseng.

Ka lialloi tsa aluminium, Sc e potlaka joalo ka Al₃Sc e hokahaneng, e eketsa mocheso oa recrystallization le ho hatella ho hoholeha ha lijo-thollo.

Ha e kopantsoe le Zr, likaroloana tse tsitsitseng tsa Al₃(Sc,Zr) tse nang le mocheso o phahameng oa mocheso o phahameng, tse khothalletsang lijo-thollo tse lekaneng le ho thibela ho sisinyeha le ho falla ha lijo-thollo. Sena se ntlafatsa matla, ho hanyetsa mokhathala, le ts'ebetso ea khatello ea maikutlo.

Excessive Sc e ka lebisa ho likaroloana tsa Al₃ (Sc, Zr) tse mahoashe, ho fokotsa bokhoni ba ho kopanya, matla le ductility.

Erbium (Er)

Er e sebetsa ka mokhoa o ts'oanang le Sc empa e na le litšenyehelo tse ngata.

Ka li-alloys tsa 7xxx, litlatsetso tse loketseng tsa Er li ntlafatsa lijo-thollo, li thibela ho sisinyeha ha sekhahla le ho falla ha moeli oa lijo-thollo, li hatella recrystallization, le ho matlafatsa matla.

Ha e kopantsoe le Zr, Al₃ (Er, Zr) likaroloana li theha, tse tsitsitseng haholoanyane ho feta Al₃Er feela, tse fanang ka khatello e ntle ea recrystallization.

Er e feteletseng e ka hlahisa mekhahlelo ea Al₈Cu₄Er, e fokotsang matla le ductility ka bobeli.

Gadolinium (Gd)

Keketso e itekanetseng ea Gd e ntlafatsa lijo-thollo, e eketsa matla le ho tsitsa, le ho matlafatsa ho qhibiliha ha Zn, Mg, le Cu ka har'a matrix.

Sephetho sa sephetho sa Al₃(Gd,Zr) se kheloha le meeli ea li-subgrain, ho hatella recrystallization. Filimi e sebetsang e boetse e theha holim'a lijo-thollo, e fokotsang kholo ea lijo-thollo.

Gd e feteletseng e ka baka ho hohla ha lijo-thollo le ho senya thepa ea mochini.

Lanthanum (La), Cerium (Ce), le Yttrium (Y)

La e hloekisa lijo-thollo, e fokotsa oksijene, 'me e etsa filimi e sebetsang holim'a lijo-thollo ho thibela kholo.

La le Ce li khothalletsa GP zone le η′ phase precipitation, ho ntlafatsa matla a matrix le ho hanyetsa ho bola.

Y e hloekisa matrix, e sitisa ho qhibiliha ha likarolo tse kholo tsa alloying ka tharollo e tiileng, e khothalletsa nucleation, 'me e fokotsa phapang e ka bang teng pakeng tsa meeli ea lijo-thollo le ka hare, ho matlafatsa ho hanyetsa ha kutu.

Ho feteletseng La, Ce, kapa Y ho ka lebisa ho metsoako e thata ea blocky, e fokotsang ductility le matla.

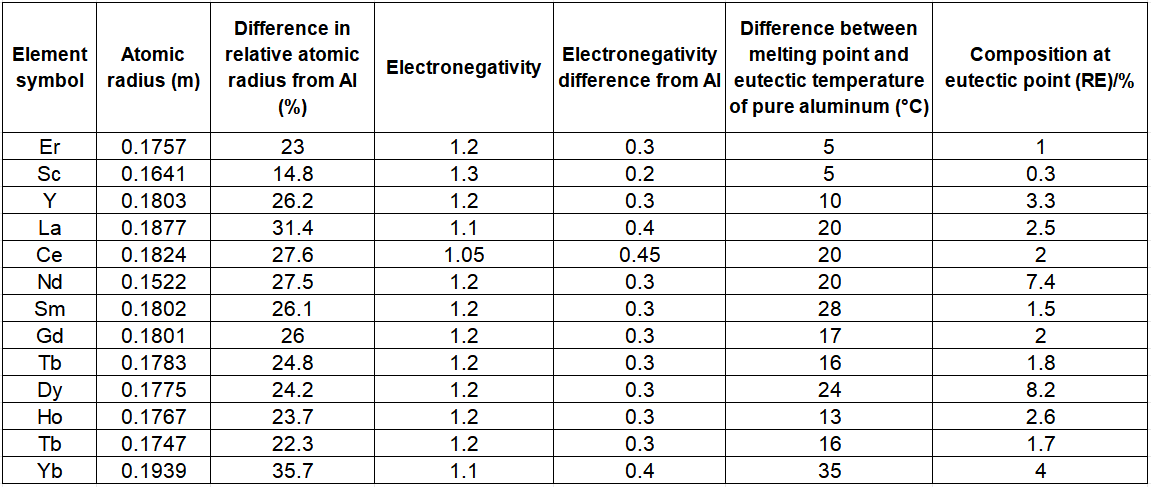

Thepa ea likarolo tse kholo tsa lefats'e tse sa tloaelehang le litšobotsi tsa tsona ka aluminium

Nako ea poso: Aug-21-2025