6063 aluminium alloy ke ea alloy e tlase ea Al-Mg-Si letoto la aluminium e phekolehang mocheso. E na le ts'ebetso e ntle ea ho bopa ha extrusion, ho hanyetsa kutu e ntle le thepa e felletseng ea mochini. E boetse e sebelisoa haholo indastering ea likoloi ka lebaka la 'mala oa eona o bonolo oa oxidation. Ka ho potlakisa mokhoa oa likoloi tse bobebe, ts'ebeliso ea lisebelisoa tsa 6063 tsa aluminium alloy extrusion indastering ea likoloi le eona e eketsehile le ho feta.

The microstructure le thepa ea thepa extruded angoa ke ho kopantswe liphello tsa extrusion lebelo, extrusion mocheso le extrusion ratio. Har'a bona, karo-karolelano ea extrusion e khethoa haholo ke khatello ea extrusion, katleho ea tlhahiso le lisebelisoa tsa tlhahiso. Ha karo-karolelano ea extrusion e nyane, deformation ea alloy e nyane mme ntlafatso ea microstructure ha e hlake; ho eketsa karo-karolelano ea extrusion ho ka ntlafatsa haholo lijo-thollo, ho senya karolo ea bobeli e mahoashe, ho fumana microstructure e ts'oanang, le ho ntlafatsa thepa ea mochine oa motsoako.

Li-alloys tsa 6061 le 6063 tsa aluminium li na le recrystallization e matla nakong ea ts'ebetso ea extrusion. Ha mocheso oa extrusion o ntse o le teng, ha karo-karolelano ea extrusion e ntse e eketseha, boholo ba lijo-thollo bo fokotseha, mohato o matlafatsang o qhalakanngoa hantle, 'me matla a tsitsipano le alloy ea alloy a eketseha ka tsela e loketseng; leha ho le joalo, ha karo-karolelano ea extrusion e ntse e eketseha, matla a extrusion a hlokahalang bakeng sa ts'ebetso ea extrusion a boetse a eketseha, a baka phello e kholo ea mocheso, e leng se etsang hore mocheso o ka hare oa motsoako o phahame, 'me ts'ebetso ea sehlahisoa e fokotsehe. Teko ena e ithuta phello ea karo-karolelano ea extrusion, haholo-holo karo-karolelano e kholo, ho microstructure le thepa ea mochini ea 6063 aluminium alloy.

1 Lisebelisoa le mekhoa ea liteko

Lisebelisoa tsa liteko ke 6063 aluminium alloy, 'me lik'hemik'hale tsa lik'hemik'hale li bontšoa ho Lethathamo la 1. Boholo ba pele ba ingot ke Φ55 mm × 165 mm, 'me bo kenngoa ka billet ea extrusion ka boholo ba Φ50 mm × 150 mm ka mor'a phekolo ea homogenization ho 560 ℃ bakeng sa 6 h. Billet e futhumetse ho 470 ℃ 'me e lula e futhumetse. Mocheso oa preheating oa barrel ea extrusion ke 420 ℃, 'me mocheso oa ho futhumatsa oa hlobo ke 450 ℃. Ha lebelo la extrusion (extrusion rod falling speed) V = 5 mm / s e ntse e sa fetohe, lihlopha tse 5 tsa liteko tse fapaneng tsa extrusion li etsoa, 'me litekanyetso tsa extrusion R ke 17 (tse lumellanang le bophara ba lesoba la D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 6 mm), 69 (D = 6 mm), 69 (D = 6 mm).

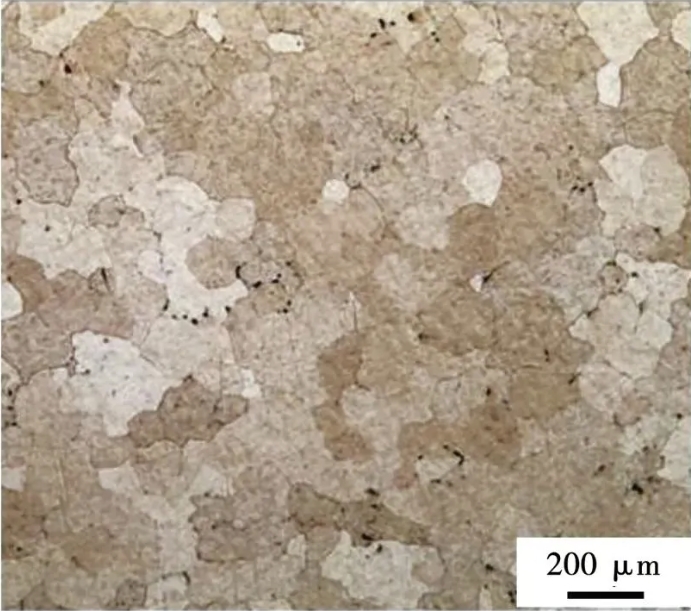

Letlapa la 1 Liqapi tsa lik'hemik'hale tsa 6063 Al alloy (wt/%)

Kamora ho sila ha sandpaper le ho bentša ka mochini, disampole tsa metallographic li ile tsa hlophisoa ka reagent ea HF e nang le karoloana ea molumo oa 40% bakeng sa 25 s, mme sebopeho sa metallographic sa disampole se ile sa bonoa ka microscope ea LEICA-5000 optical. Mohlala oa tlhahlobo ea sebopeho se nang le boholo ba 10 mm × 10 mm se ile sa khaoloa ho tloha bohareng ba karolo ea longitudinal ea molamu oa extruded, 'me ho sila ka mechine le ho ts'oara ho ile ha etsoa ho tlosa lera la khatello ea holimo. Lipalo tse sa fellang tsa lipalo tse tharo tsa kristale {111}, {200}, le {220} tsa sampole li lekantsoe ka X'Pert Pro MRD X-ray diffraction analyser ea PANalytical Company, 'me boitsebiso bo entsoeng bo ile ba sebetsoa le ho hlahlojoa ke X'Pert Data View le X'Pert Texture software.

Setšoantšo se tsitsitseng sa alloy cast alloy se nkiloe bohareng ba ingot, 'me mohlala o tsitsitseng o ile oa khaoloa ho latela tataiso ea extrusion ka mor'a extrusion. Boholo ba sebaka sa gauge e ne e le Φ4 mm×28 mm. Teko e matla e entsoe ho sebelisoa mochini oa tlhahlobo ea lisebelisoa tsa bokahohleng oa SANS CMT5105 o nang le sekhahla sa 2 mm/min. Kakaretso ea boleng ba mehlala e meraro e tloaelehileng e ne e baloa e le data ea thepa ea mochine. Ho robeha ha morphology ea mehlala e tsitsitseng ho ile ha hlokomeloa ho sebelisoa maekerosekoupo ea elektronike e phahameng haholo (Quanta 2000, FEI, USA).

2 Liphetho le lipuisano

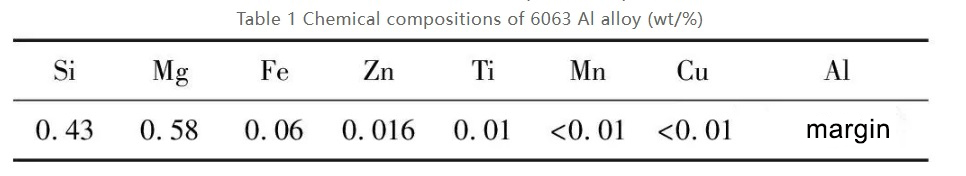

Setšoantšo sa 1 se bontša metallographic microstructure ea as-cast 6063 aluminium alloy pele le ka mor'a phekolo ea homogenization. Joalokaha ho bontšitsoe setšoantšong sa 1a, lithollo tsa α-Al ka microstructure ea as-cast li fapana ka boholo, palo e kholo ea mekhahlelo ea reticular β-Al9Fe2Si2 e bokana meeling ea lijo-thollo, 'me palo e kholo ea mekhahlelo ea granular Mg2Si e teng ka hare ho lijo-thollo. Ka mor'a hore ingot e be homogenized ho 560 ℃ bakeng sa 6 h, karolo ea eutectic e sa leka-lekaneng pakeng tsa li-alloy dendrites e ile ea qhibiliha butle-butle, metsoako ea alloy e ile ea qhibiliha ka har'a matrix, microstructure e ne e le junifomo, 'me boholo ba lijo-thollo bo ne bo ka ba 125 μm (Setšoantšo sa 1b).

Pele ho homogenization

Ka mor'a ho fana ka phekolo ea uniformizing ka 600 ° C bakeng sa lihora tse 6

Setšoantšo sa 1 Metallographic sebopeho sa 6063 aluminium alloy pele le ka mor'a phekolo ea homogenization

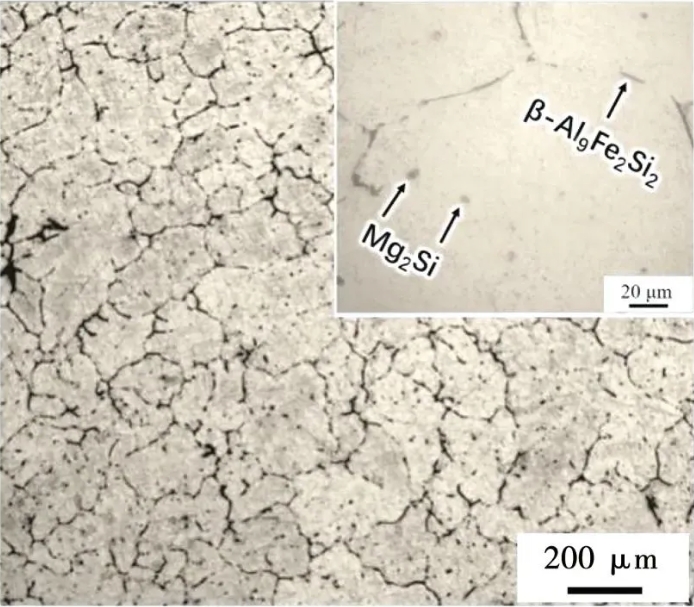

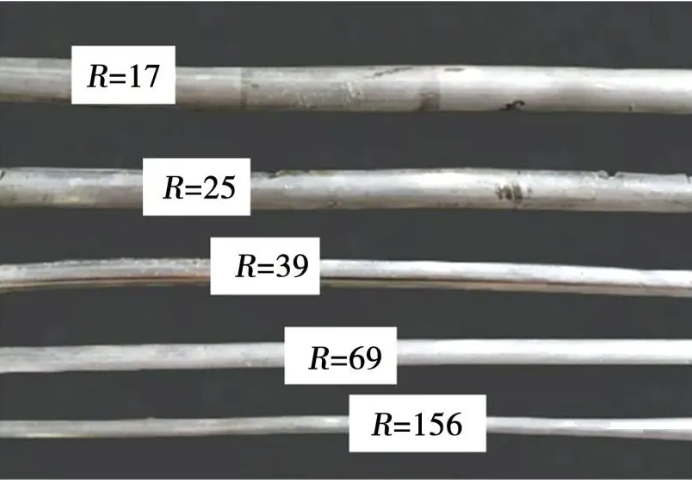

Setšoantšo sa 2 se bonts'a ponahalo ea li-alloy tsa 6063 tsa aluminium tse nang le likarolo tse fapaneng tsa extrusion. Joalokaha ho bontšitsoe setšoantšong sa 2, boleng ba holim'a li-alloy tsa 6063 tsa aluminium tse fetisitsoeng ka likarolo tse fapaneng tsa extrusion li ntle, haholo-holo ha karo-karolelano ea extrusion e eketsoa ho 156 (e tsamaellanang le lebelo la ho tsoa ha bar extrusion ea 48 m/min), ho ntse ho se na bofokoli ba extrusion joalo ka mapetsong le ho ebola, le 60 aluminium e nang le aluminium e ntle holim'a allo60. hot extrusion ho etsa tshebetso tlas'a lebelo le leholo le karo-karolelano e khōlō extrusion.

Setšoantšo sa 2 Ponahalo ea lithupa tsa 6063 tsa aluminium tse nang le likarolo tse fapaneng tsa extrusion.

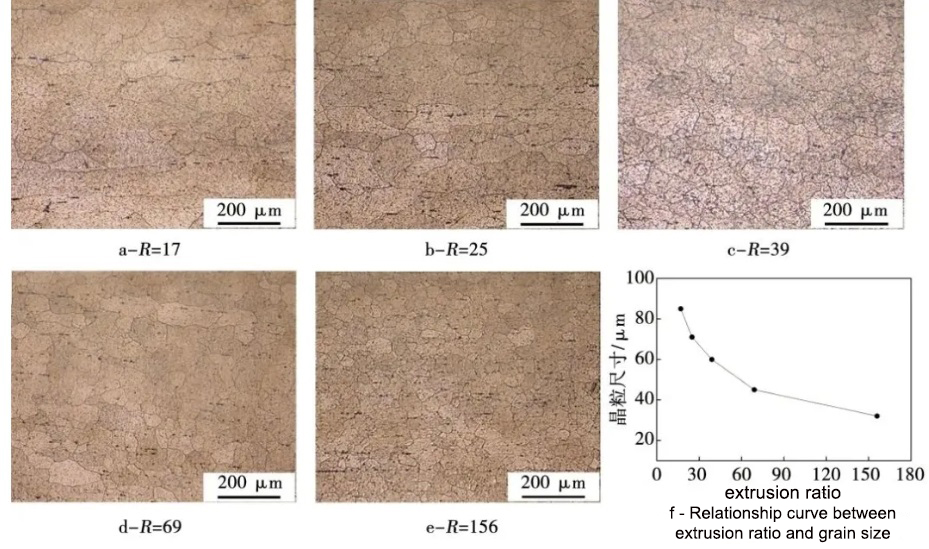

Setšoantšo sa 3 se bontša metallographic microstructure ea karolo ea longitudinal ea 6063 aluminium alloy bar e nang le likarolo tse fapaneng tsa extrusion. Sebopeho sa lijo-thollo sa bar se nang le likarohano tse fapaneng tsa extrusion se bonts'a likhato tse fapaneng tsa bolelele kapa ntlafatso. Ha karo-karolelano ea extrusion e le 17, lithollo tsa pele li lelefalitsoe ho latela tataiso ea extrusion, li tsamaisana le ho thehoa ha palo e nyenyane ea lijo-thollo tse nchafalitsoeng, empa lithollo li ntse li le mahoashe, ka boholo ba lijo-thollo tse ka bang 85 μm (Setšoantšo sa 3a); ha karo-karolelano ea extrusion e le 25, lithollo li huloa ho feta tse tšesaane, palo ea lijo-thollo tse nchafalitsoeng e eketseha, 'me boholo ba lijo-thollo bo fokotseha hoo e ka bang 71 μm (Setšoantšo sa 3b); ha karo-karolelano ea extrusion ke 39, ntle le palo e nyenyane ea khoahlapisitseng, microstructure ha e le hantle e entsoe ka equiaxed recrystallized lijo-thollo tsa boholo bo sa leka-lekaneng, le boholo ba lijo-thollo karolelano ea hoo e ka bang 60 μm (Figure 3c); ha karo-karolelano ea extrusion e le 69, ts'ebetso e matla ea recrystallization e phethiloe, lithollo tsa pele tse mahoashe li fetotsoe ka ho feletseng hore e be lijo-thollo tse entsoeng ka mokhoa o ts'oanang, 'me boholo ba lijo-thollo bo hloekisitsoe hoo e ka bang 41 μm (Setšoantšo sa 3d); ha karo-karolelano ea extrusion ke 156, ka tsoelo-pele e feletseng ea ts'ebetso e matla ea recrystallization, microstructure e tšoana haholo, 'me boholo ba lijo-thollo bo hloekisitsoe haholo hoo e ka bang 32 μm (Setšoantšo sa 3e). Ka ho eketseha ha karo-karolelano ea extrusion, ts'ebetso e matla ea recrystallization e tsoela pele ka botlalo, alloy microstructure e fetoha e ts'oanang, 'me boholo ba lijo-thollo bo hloekisitsoe haholo (Setšoantšo sa 3f).

Setšoantšo sa 3 Sebopeho sa Metallographic le boholo ba lijo-thollo tsa karolo ea longitudinal ea 6063 aluminium alloy rods e nang le likarolo tse fapaneng tsa extrusion.

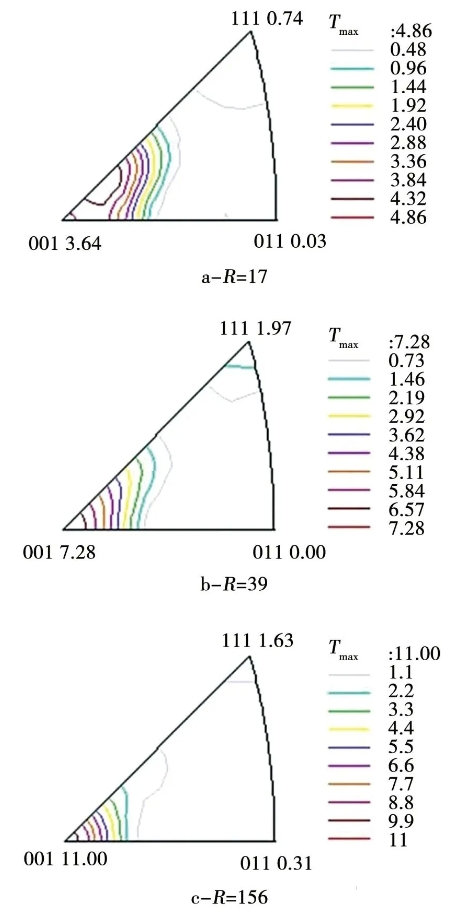

Setšoantšo sa 4 se bonts'a lipalo tse fapaneng tsa lipalo tsa 6063 aluminium alloy bars tse nang le likarolo tse fapaneng tsa extrusion ho latela tataiso ea extrusion. Ho ka bonoa hore li-microstructures tsa li-alloy bar tse nang le li-ratios tse fapaneng tsa extrusion kaofela li hlahisa mokhoa o hlakileng oa ho khetha. Ha tekanyo ea extrusion e le 17, ho fokola <115>+ <100> ho thehoa (Setšoantšo sa 4a); ha karo-karolelano ea extrusion e le 39, likarolo tsa sebopeho ke tsona tse matla haholo <100> lesela le fokolang le fokolang <115> sebopeho (Setšoantšo sa 4b); ha karo-karolelano ea extrusion ke 156, likarolo tsa motsoako ke <100> sebopeho se nang le matla a mangata a eketsehileng, ha <115> sebopeho se nyamela (Setšoantšo sa 4c). Liphuputso li bontšitse hore li-cubic metals tse bohareng ba sefahleho li theha haholo <111> le <100> masela a terata nakong ea extrusion le ho taka. Hang ha sebopeho se thehoa, mocheso oa kamore ea mochine oa motsoako o bontša anisotropy e hlakileng. Matla a matla a eketseha ka ho eketseha ha karo-karolelano ea extrusion, e bontšang hore palo ea lijo-thollo ka tsela e itseng ea kristale e bapileng le tataiso ea extrusion ka motsoako e eketseha butle-butle, 'me matla a longitudinal tensile a alloy a eketseha. Mekhoa e matlafatsang ea lisebelisoa tse chesang tsa 6063 aluminium alloy extrusion e kenyelletsa ho matlafatsa lijo-thollo tse ntle, ho matlafatsa ho senya, ho matlafatsa sebopeho, joalo-joalo Ka har'a mefuta e mengata ea mekhoa e sebelisoang thutong ena ea liteko, ho eketsa tekanyo ea extrusion ho na le phello e khothalletsang mekhoa e ka holimo e matlafatsang.

Setšoantšo sa 4 Setšoantšo sa morao-rao sa lithupa tsa aluminium tse 6063 tse nang le likarolo tse fapaneng tsa extrusion ho latela tataiso ea extrusion.

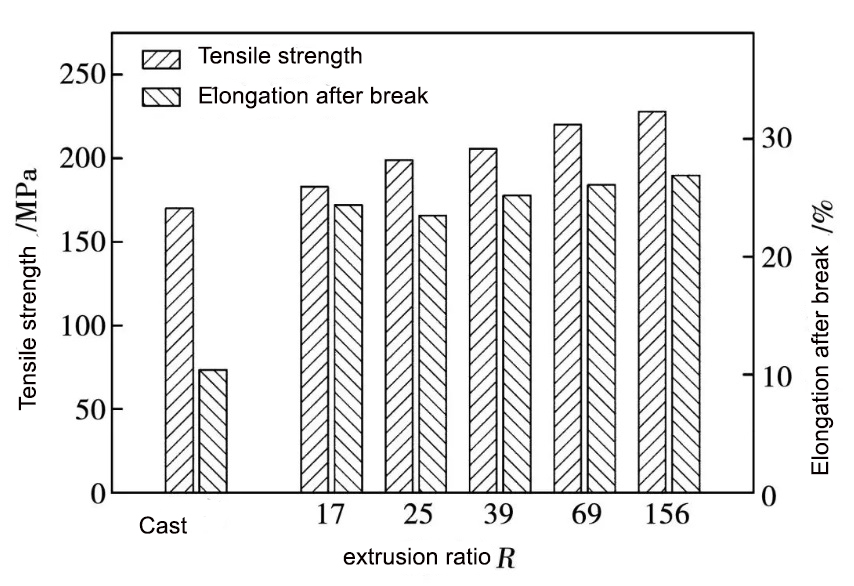

Setšoantšo sa 5 ke histogram ea thepa ea tensile ea 6063 aluminium alloy ka mor'a deformation ka likarolo tse fapaneng tsa extrusion. Matla a matla a alloy cast ke 170 MPa le bolelele ke 10.4%. Matla a tsitsipano le bolelele ba alloy ka mor'a extrusion li ntlafatsoa haholo, 'me matla a tsitsipano le bolelele bo eketseha butle-butle ka keketseho ea karolelano ea extrusion. Ha karo-karolelano ea extrusion e le 156, matla a tensile le alloy alloy a fihla boleng bo phahameng, e leng 228 MPa le 26,9%, ka ho latellana, e ka bang 34% e phahameng ho feta matla a matla a alloy le hoo e ka bang 158% e phahameng ho feta elongation. The tensile matla a 6063 alloy aluminium alloy e fumanoang ka tekanyo e kholo ea extrusion e haufi le matla a matla a matla (240 MPa) a fumanoang ke 4-pass lekanang le kanale ea angular extrusion (ECAP), e leng holimo haholo ho feta matla a matla a matla (171.1 MPa) a fumanoang ke 1-pass ECAP extrusion ea 6063 aluminium alloy. Ho ka bonoa hore karo-karolelano e kholo ea extrusion e ka ntlafatsa thepa ea mochini oa alloy ho isa tekanyong e itseng.

Ntlafatso ea thepa ea mochini ea alloy ka karo-karolelano ea extrusion haholo-holo e tsoa ho matlafatso ea ntlafatso ea lijo-thollo. Ha tekanyo ea extrusion e ntse e eketseha, lijo-thollo lia hloekisoa 'me sekhahla sa ho senya sea eketseha. Meeli e mengata ea lijo-thollo sebakeng se seng le se seng e ka sitisa ka katleho ho sisinyeha ha li-dislocation, ho kopantsoe le ho tsamaisana le ho ts'oaroa ha li-dislocation, kahoo ho ntlafatsa matla a alloy. Ha lijo-thollo li le ntle, ho na le meeli e boima haholoanyane ea lijo-thollo, le deformation ea polasetiki e ka qhalakanngoa ka lijo-thollo tse ngata, tse sa lumellaneng le ho thehoa ha mapetsong, ho sa tsotellehe ho phatlalatsoa ha mapetsong. Matla a mangata a ka kenngoa nakong ea ts'ebetso ea fracture, kahoo a ntlafatsa polasetiki ea motsoako.

Fig.5 thepa ea Tensile ea 6063 aluminium alloy ka mor'a ho lahla le ho hlahisa

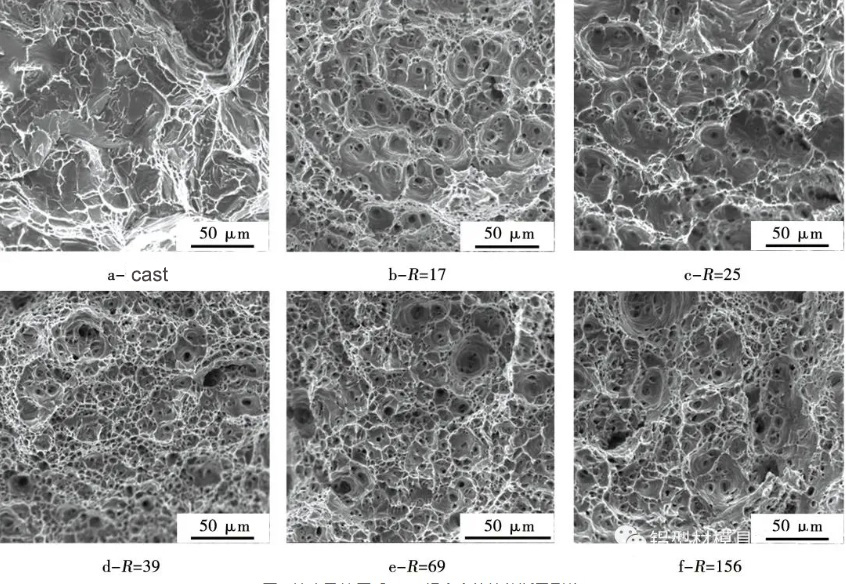

The tensile fracture morpholoji ea motsoako ka mor'a deformation le karo-karolelano fapaneng extrusion ho bontšoa Figure 6. Ha ho dimples ile a fumanoa ka fracture morpholoji ea e le-lahlela sampole (Figure 6a), 'me fracture ne haholo-holo entsoe ka libaka tse bataletseng le metshetshe tabola, e bontšang hore tensile fracturettle mochine e ne e le ka sehloohong-fracture ea fracture e le ka sehloohong-fracture. The fracture morpholoji ea motsoako ka mor'a extrusion e fetohile haholo, 'me fracture e entsoe ka palo e kholo ea dimples equiaxed, e bontšang hore fracture mochine oa motsoako ka mor'a extrusion fetohile ho tloha brittle fracture ho ductile fracture. Ha karo-karolelano ea extrusion e nyenyane, li-dimples li sa teba 'me boholo ba dimple bo boholo,' me kabo e sa lekana; ha karo-karolelano ea extrusion e ntse e eketseha, palo ea li-dimples e ntse e eketseha, boholo ba dimple bo nyenyane 'me kabo e tšoana (Setšoantšo sa 6b ~ f), e leng se bolelang hore motsoako o na le polasetiki e ntle, e lumellanang le liphello tsa tlhahlobo ea thepa ea mochine ka holimo.

3 Qetello

Tekong ena, liphello tsa likarolo tse fapaneng tsa extrusion ho microstructure le thepa ea 6063 aluminium alloy li ile tsa hlahlojoa tlas'a boemo ba hore boholo ba billet, mocheso oa mocheso oa ingot le lebelo la extrusion li ile tsa lula li sa fetohe. Liphetho ke tse latelang:

1) Recrystallization e matla e etsahala ka 6063 aluminium alloy nakong ea extrusion e chesang. Ka ho eketseha ha karo-karolelano ea extrusion, lijo-thollo li ntse li hloekisoa ka mokhoa o tsoelang pele, 'me lijo-thollo tse lelefalitsoeng haufi le tataiso ea extrusion li fetoloa lijo-thollo tse nang le equiaxed recrystallized,' me matla a <100> terata a ntse a eketseha.

2) Ka lebaka la phello ea ho matlafatsa lijo-thollo tse ntle, thepa ea mochine ea alloy e ntlafatsoa ka ho eketseha ha tekanyo ea extrusion. Ka har'a mefuta e mengata ea liteko, ha karo-karolelano ea extrusion e le 156, matla a tensile le bolelele ba alloy a fihla ho boleng bo phahameng ba 228 MPa le 26.9%, ka ho latellana.

Fig.6 Tensile fracture morphologies ea 6063 aluminium alloy ka mor'a ho lahla le ho tsoa.

3) The fracture morphology ea mohlala oa as-cast e entsoe ka libaka tse bataletseng le mathōko a tabohileng. Ka mor'a extrusion, fracture e entsoe ka palo e kholo ea li-dimples tse lekanang, 'me mochine oa fracture o fetoloa ho tloha ho brittle fracture ho ea ho ductile fracture.

Nako ea poso: Nov-30-2024